Contents

What is the

Gemini Spacecraft Computer (OBC)?

The Gemini spacecraft computer is, as the name implies, the onboard

computer of the Gemini spacecraft. The computer seems to have

been referred to variously as the "spacecraft computer", the

"digital computer", or the "On-Board Computer" (OBC). It

was the Gemini equivalent of Apollo's AGC, though with more limited

capabilities and functionality. Its basic use was in the

post-launch phases of missions (orbit phase, retrograde phase,

re-entry phase), because the Titan II rocket which carried the

Gemini spacecraft into orbit was guided by its own (separate) ACS-15

guidance computer, but there was provision also for switchover to

the Gemini computer for backup guidance if the need arose.

Interestingly, the OBC could be used for automatic attitude control

of the spacecraft, but not automatic velocity control; rather, it

performed necessary calculations for maneuvers such as orbital

insertion or re-entry, and the pilots then performed the manual

chores of actually adjusting the spacecraft velocity appropriately.

The OBC was designed and manufactured by IBM's Federal Systems

Division, in Owego, New York, just as Apollo's Launch

Vehicle Digital Computer (LVDC) was. The OBC and the

LVDC are extraordinarily similar at the CPU level.

The Gemini VIII OBC, with

cover removed

(Smithsonian National Air & Space Museum)

|

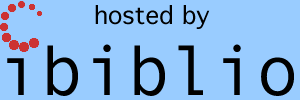

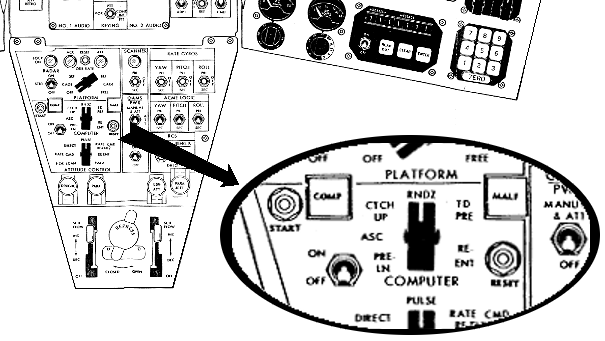

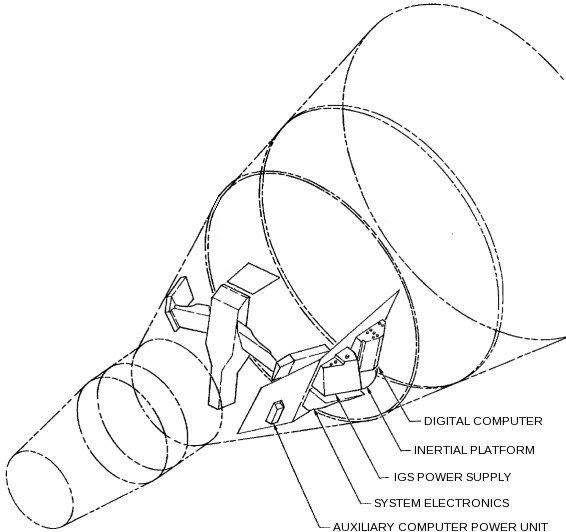

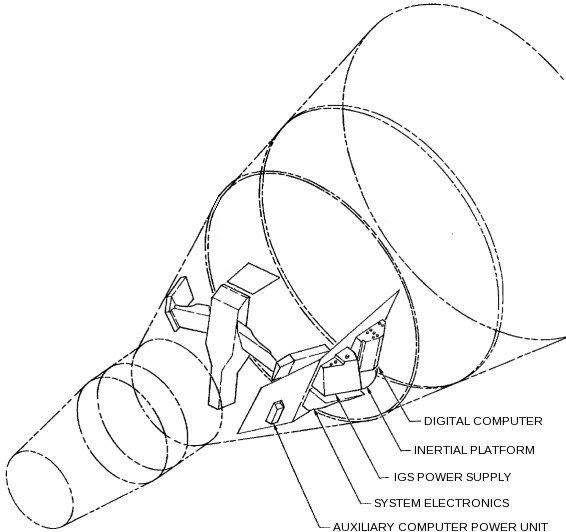

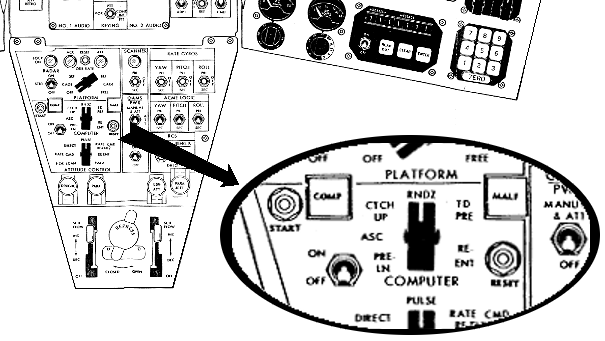

Location of the OBC in the

spacecraft

|

Peripheral

Devices

This section contains a general overview of the OBC's peripheral

devices, but many of them are discussed in much greater detail in

later sections.

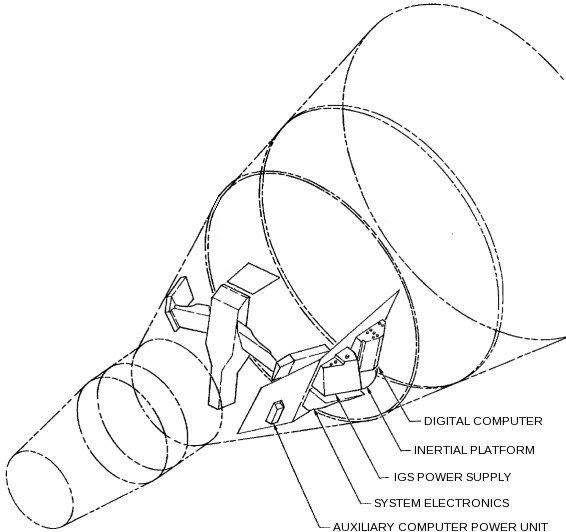

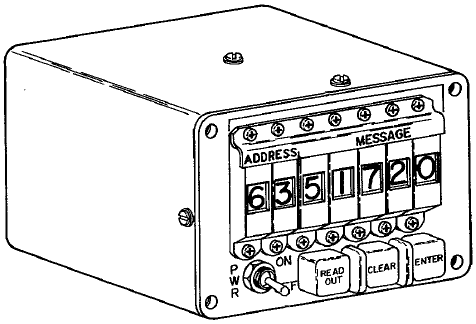

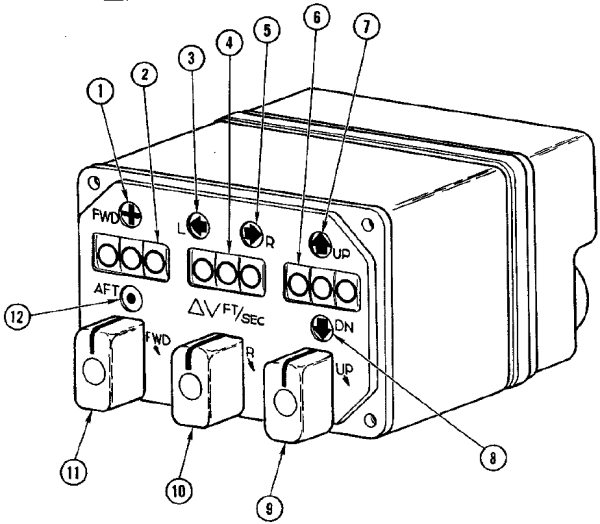

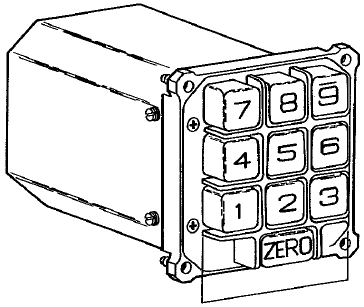

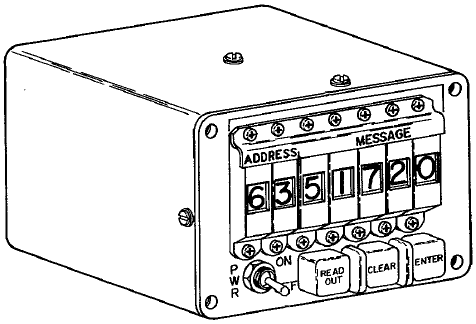

From a user standpoint, the most visible of the OBC's peripheral

device was the Manual Data Insertion Unit (MDIU)—the Gemini

equivalent of the Apollo DSKY—which

comprised the Modular Display Keyboard (MDK) and the Modular Display

Readout (MDR).

Modular Display Keyboard

(MDK)

|

Modular Display Readout

|

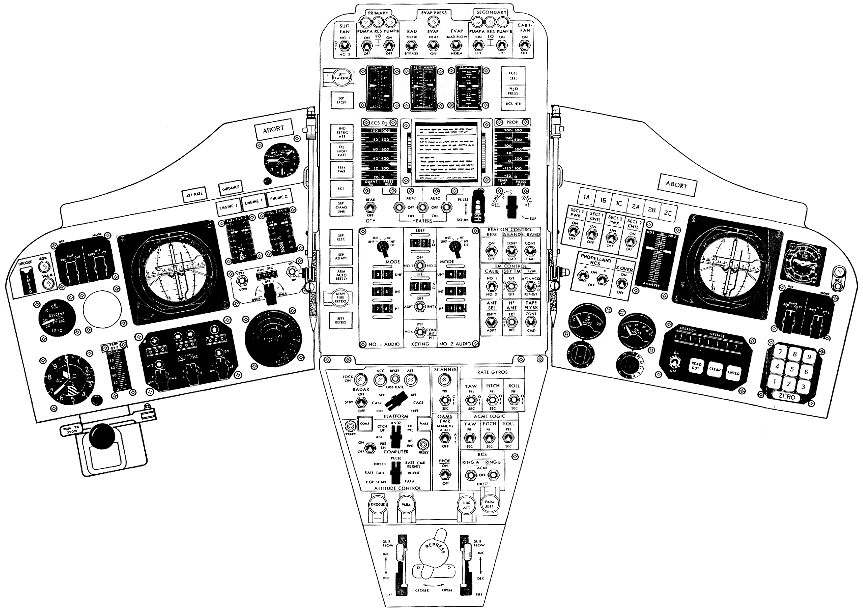

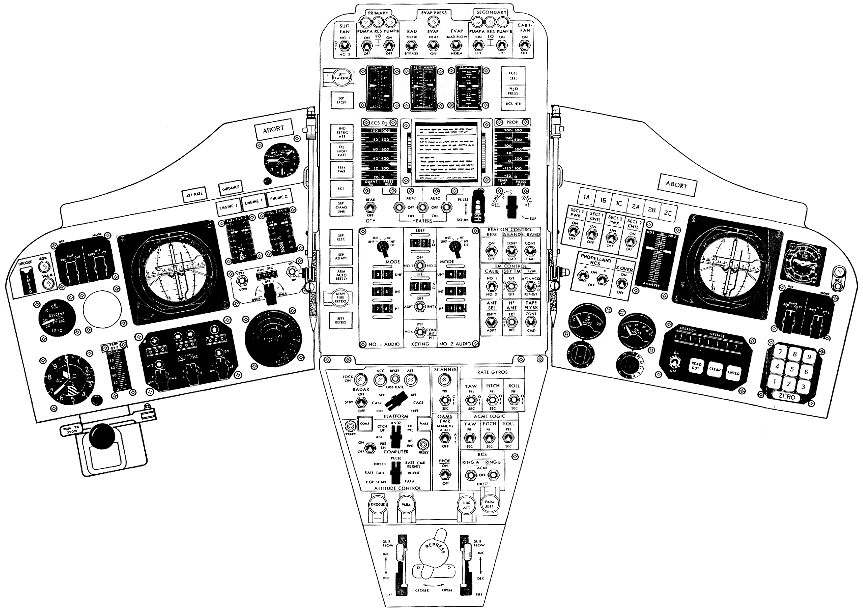

These were on the Pilot's (as opposed to the Command Pilot's) side

of the control panel, at the lower right in the drawing below.

The small image below is from the familiarization manual, but if you

click on it you'll get a much bigger, much more detailed drawing

from the Gemini 5 Mission Report.

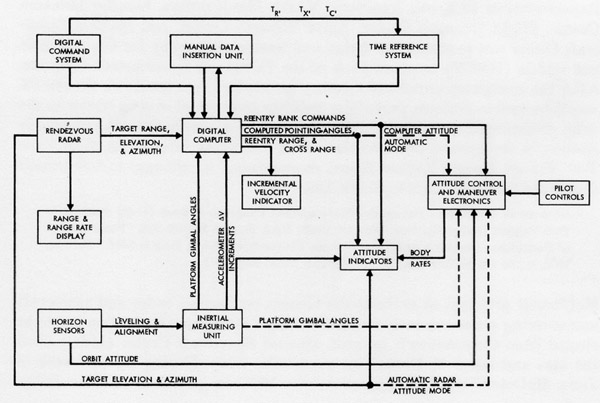

A basic inventory of the guidance sub-systems includes:

- Attitude Control and Maneuver Electronics (ACME), which is

the sub-system that directly controls the propulsion system.

- Inertial Guidance System (IGS), including the Inertial

Measurement Unit (IMU) and the OBC itself.

- Horizon Sensors

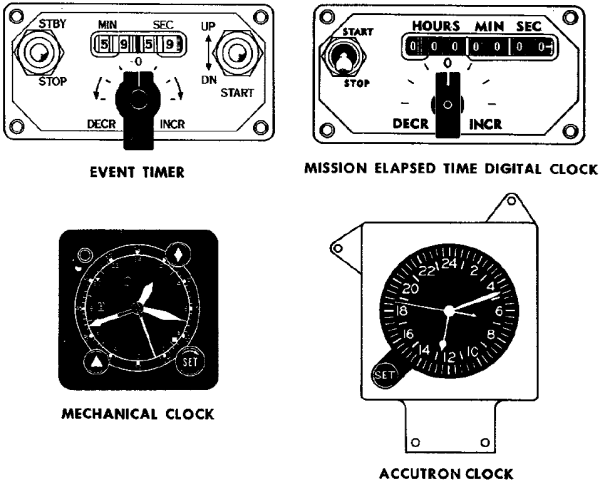

- Time Reference System (TRS)

The diagram below shows a very simplified block diagram of the

guidance system, but if you click it you'll get a (different)

more-detailed block diagram.

The IMU is the usual gimballed stable platform with

accelerometers and angular resolvers as in Apollo, except for a

key difference that the Gemini IMU had four gimbals rather than

the three gimbals of Apollo. This means that it was not

subject to the phenomenon of "gimbal lock", and hence the

software used to adjust spacecraft alignment could be simpler

than with three gimbals. The value of the 4th gimbal can

be appreciated when considering incidents like the mishap in

Gemini VIII in which an uncontrolled roll occurred. (If

the IMU had had only three gimbals, my understanding is that

gimbal lock would have occurred when the roll angle was too

great.) On the other hand, at that point the spacecraft

was under manual control anyway, and I'm sure that the notion

that the IMU would have to be realigned later would have been

the least of Neil Armstrong and Dave Scott's worries.

Gemini

Documentation

Sadly, documentation we've been able to collect for the OBC lags far

behind that of the AGC or even that of the Abort Guidance System

(AGS). What little survives that we have been able to access

can be found in our Document Library.

There's a lot of unique stuff there contributed by original Gemini

developers.

Of particular note are the portions of the Gemini Operations

Handbook, for spacecraft 7 and 10, and especially subsection

2.5.7 of those handbooks. These provide user instructions for

the flight-computer software, and in the case of spacecraft 10 are

particularly detailed. For example, in the case of spacecraft

10, there's a complete list, with explanations, scope, and format,

of all of the memory variables (addresses 0-162) accessible from the

MDIU/DCS.

Evolution of the

Flight Software ... or, "Everybody Loves Math Flow 7" ... or,

"What is software, my man? What is software?"

Information about the Gemini OBC software is hard to come by.

Useful information we don't

have includes any actual OBC software that's contemporary to the

Gemini project itself, and that's a lot not to know. But the

situation isn't all bad, partly because the development method of

the Gemini OBC software causes us to question what the notion of

having the original software even means. I'll explain more

about that shortly, but there's an important sense in which we

actually do have significant portions of the software at our

disposal.

But before turning our attention to such lofty matters, let's begin

with some of the more-mundane details. Firstly, as far as

naming is concerned, the flight software seems to have been called

simply the "operational program". On the subject of

versioning of the operational program, we have only partial

information, from the familiarization manual, from James

Tomayko's

Computers in Spaceflight, Chapter 1, section 4, and from this short memo.

(Where there's any discrepancy, I personally believe in the memo.)

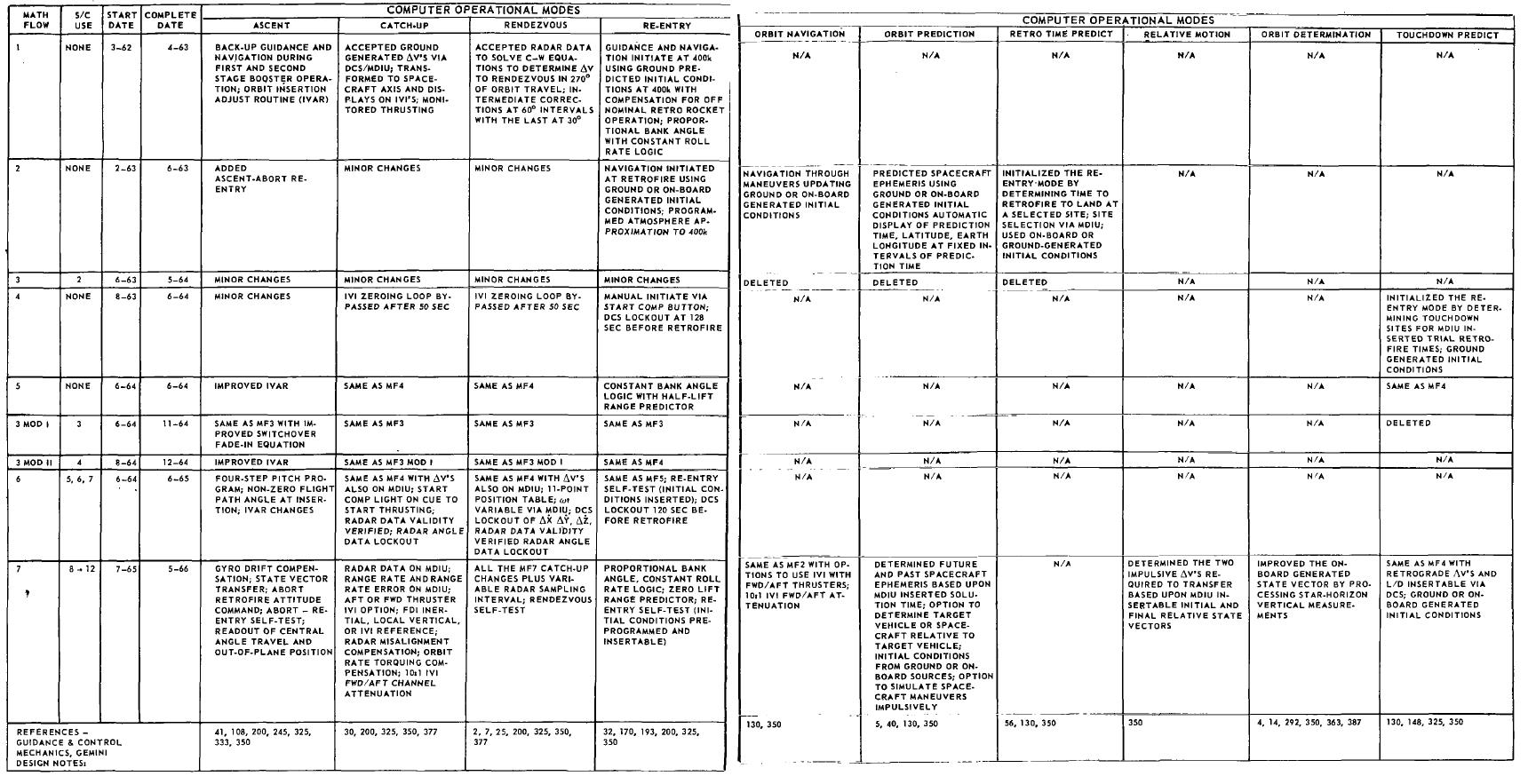

The operational programs were characterized in terms of something

called the "Math Flow". In brief, the Math Flow is the

complete design of the software, expressed in Gemini as a series of

very detailed flowcharts. The development of the Math Flow

eventually went through 7 major versions, designated MF-1 through

MF-7. But there were differing revisions for each of the major

versions as well.

The overall software design was partitioned into several different

areas of basic functionality. In math-flow MF-1 through MF-6, these

functional areas were integrated into a single operational

program. (Though for some missions, unneeded functionality

could be omitted. Thus, Catch-up & Rendezvous were omitted in

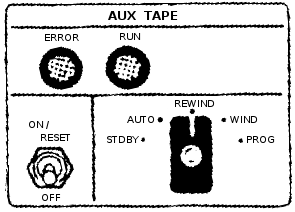

spacecraft GT-3, GT-4, and GT-7.) In MF-7, the code was

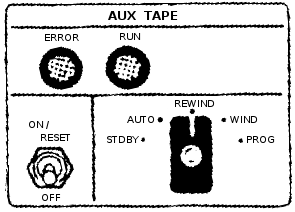

refactored into 6 different high-level "Program Modules", which

could be loaded into memory from the Auxiliary Tape Memory

(ATM) when needed during specific mission phases, though

Module I was in memory at all times and didn't need to be loaded

from the ATM. The modules were as follows:

Module

|

Basic Functionality

|

MOD I

|

Executor

Pre-Launch

Diagnostics

Computational subroutines (SINCOS, SQROOT, etc.)

ATM-read

|

MOD II

|

Ascent (with abort

capability)

Catch-up (without radar)

Re-entry for ascent-abort

|

MOD III

|

Catch-up (with radar)

Rendezvous

|

MOD IV

|

Touchdown-predict

Re-entry

Re-entry initialization

|

MOD V

|

Simplified functions as

backup for ATM failure:

Ascent (without abort

capability)

Catch-up and Rendezvous (without self-test)

|

MOD VI

|

Orbit-predict

Orbit-navigation

Orbit-determination

|

And here's a more-detailed breakdown if the evolution and usage of

these modules on math-flow by math-flow basis:

The astronauts used the Computer Mode rotary switch on the Pilots' Control and Display Panel to select from

amount the following mission phases to indirectly affect the active

functionality areas: Pre-launch, Ascent, Catch-up, Rendezvous,

or Re-entry.

All of these functionality areas are self-explanatory, except

"Executor". Executor is the interface that interrelates the

other software modules and allows them to interact with each other,

as well has implementing certain common functionality among them.

Here's another breakdown, this time mine:

Spacecraft

|

Mission

Designation

|

Math

Flow

version

|

Program

number,

revision

|

Comments

|

GT-1

|

Gemini 1

|

n/a

|

n/a

|

Unmanned mission.

Since Gemini I was apparently intended principally as a

structural test of the spacecraft, it may not have had a

computer onboard.

|

n/a

|

n/a

|

MF-1

|

-

|

|

n/a

|

n/a

|

MF-2

|

-

|

|

n/a

|

n/a

|

MF-3

|

6444540, B |

Flowcharts that we have! Seemingly, one minor revision

prior to the software flown in the Gemini 2 unmanned

mission. You'll notice, though, that the first manned

missions (Gemini 3 and 4) still used MF-3, though in a later

minor revision. It's useful to know that:

- Rendezvous begins on p. 1

- Gimbal Angle and CLOCK subroutines are on p. 8

- SINCOS and ARCTAN subroutines are on p. 9

- Re-entry begins on p. 10

- SHIFT, SQRT (also computes arcsin), and LOG

subroutines are on p. 15

- MDIU subroutine is on p. 16

- Ascent guidance begins on p. 17

- Fast-loop ascent guidance begins on p. 19

- Root sum subroutine begins on p. 22

- Executor, Accelerometer, DCS, and DAS are on p. 23

- MDIU scaling stuff starts on p. 24

- AGE is on p. 26

- Standby, TRS, and I/O subroutines are on p. 27

|

n/a

|

n/a

|

MF-3(?)

|

62-564-0020, B

(Ascent Guidance and

Fast Ascent Guidance only)

|

Flowcharts that we have! See pp. 2-3 of the linked

document. The document contains a lot of other helpful

stuff like detailed explanations of the variables, some

additional theory, and source code of a FORTRAN

implementation.

I'm not really clear where this goes in the development

chronology, merely that it is a few months later than the

corresponding elements from the Detailed Math Flow in the

preceding entry.

|

GT-2

|

Gemini 2

|

MF-3

|

6444541,

C |

Unmanned mission.

|

GT-3

|

Gemini III

|

MF-3

|

6444566, C |

First manned mission.

|

GT-4

|

Gemini IV

|

MF-3

|

6444909, C

|

|

n/a

|

n/a

|

MF-4

|

-

|

Work stopped prior to "sell

off".

|

n/a

|

n/a

|

MF-5

|

-

|

Work stopped prior to release

or sell off.

|

GT-5

|

Gemini V

|

MF-6

|

6444871, B

|

|

GT-6

|

Gemini VI-A

|

MF-6

|

6444871,

D

|

|

GT-7

|

Gemini VII

|

MF-6

|

6444871, D |

|

GT-8 (backup)

|

n/a

|

MF-6

|

6444871, E

|

|

GT-8

|

Gemini VIII

|

MF-7

|

MOD I:

6449856, C

MOD II: not used

MOD III: not used

MOD IV: 6449864, B

MOD V: 6449812, B

MOD VI: not used

|

The principal difference

between MF-6 and MF-7 was the reworking of the integrated

operational program into 6 individual Modules (here referred

to as MOD I through MOD VI) that were treated as independent

programs, loadable into main memory at runtime from the new

Auxiliary Tape Memory (ATM). One consequence is that

each of the 6 Modules in MF-7 now had its own individual

program number and revision.

|

GT-9

|

Gemini IX-A

|

MF-7

|

MOD I: 6449856, C

MOD II: not used

MOD III: not used

MOD IV: 6449864, B

MOD V: 6449812, B

MOD VI: not used |

|

n/a

|

n/a

|

MF-7

|

MOD III:

6449883 |

Flowcharts that we have! Later than any Module III

flown prior to the ATM, and therefore presumably

algorithmically mature, but preceding (by some unknown

number of revisions) the first use of Module III as an

integrated program loaded from the ATM in Gemini X and

therefore presumably relatively immature in terms of its

implementation in OBC assembly language. But remember,

we don't have any of the original OBC assembly language, and

it's only the algorithmic correctness that concerns us.

Incidentally, this scan derived from a microfilm retrieved

from a wastebasket prior to the project's move from the

Washington, D.C., area in mid-1966. Obviously, we're

always trying to find better sources of material. (If

you happen to have any wastebaskets from that era that are

still loaded with microfilm, be sure to let us know.) |

GT-10

|

Gemini X |

MF-7

|

MOD I:

6449856, C (?)

MOD II: 6449816, A

MOD III: 6449895

MOD IV: 6449864, B (?)

MOD V: 6449812, B (?)

MOD VI: 6450027

|

|

GT-11

|

Gemini XI

|

MF-7

|

?

|

|

GT-12

|

Gemini XII

|

MF-7

|

?

|

|

Finally, let's return to odd question of whether or not we're in

possession of any of the original flight software. This

question is related to the serious if somewhat facetiously-phrased

question asked in this title's heading, namely: "What is

software?" In the context of the Virtual AGC project --- and I

think in the minds of most currently-active computer programmers

(2011) --- the question "What is software?" is very easily

answered: If you have the source code of the program (and some

way of compiling or assembling that code) or if you have the binary

executable of the program (and some way to execute it), then you

have the software. If you have all of the instructions for how

to compile/assemble it, so much the better. But the OBC

software developers had a somewhat different view of this question,

and their view is bound up in the method used to develop the

software.

The most important thing to understand about the

software-development process for the OBC software is that it was

very heavily dependent on design as opposed to coding. What I

mean by that is the following:

- Great attention was given to deriving the mathematics needed

for achieving the objectives, and great attention was given as

well to verifying the correctness of that mathematics.

- Then (and only then), great attention was given to developing

the "Math Flow". To repeat what I said earlier, the Math

Flow was a series of a flowcharts specifying the algorithms to

be implemented in very great detail. The flowcharts

described the algorithms in such detail that the programmer had

very few options left open to him in actually coding that

software into a form that could be compiled or assembled.

- Then (and only then), software was coded. But the coding

was almost entirely a slavish detail-by-detail translation of

the flowchart into computer source-code form.

It was interesting (and at first frustrating) for me to discuss the

matter of existence of the software with OBC developers, because

from my point of view the software (source code) seemingly no longer

existed, while from the point of view of the OBC developers the

software did still exist to the extent that the flowcharts still

existed ... because to them the software is the flowchart and not the source code.

The source code could always be reproduced from the flowchart,

albeit with great effort, and not necessarily byte-for-byte

identical to the original. When viewed from this perspective,

it makes little difference how the flowchart is translated into

computer language—whether into FORTRAN as was done for simulation

purposes or into OBC assembly language for the mission

computer—because regardless, it's the same flowchart so it's the

same program.

Now, in the preceding paragraph I probably exaggerated the OBC

developers' somewhat in order to make my point, but I think there is

nevertheless a lot of validity in the viewpoint that was

expressed: If we have the Math Flow charts, then we have the

software. You'll notice from the table above that we do have

some of the Math Flow charts, though the validity of what we have

could be debated.

I'll leave it as an exercise for the reader to decide whether or not

we actually have any of the software, or whether or not we're

rationalizing.

OBC Architecture and

Interfacing

References

The principal known sources of information about the computer itself

are the "Guidance and Control" sections (Section VIII) of the Project Gemini Familiarization Manual,

Volume 1 and Volume 2, and most

of the information on this web-page was extracted from those

sources. If you find my re-digesting of the material too poor,

you may want to read the Manual instead. However, any

simulation software, assemblers, etc., will be based on my understanding and hence on

the content of this web-page, so please bring any errors to my

attention.

Also, I should state that there's a lot of information on this page

that comes from personal communications with original OBC

developers, and can't be found in any other reference that's going

to be available to the reader ... or probably, to anyone.

While I present a general acknowledgements and "homage" to the

original OBC developers in general at the very end of this web-page,

let me mention here the OBC developers who have been so directly

helpful to me. In no particular order:

- Gene Mertz

- Charlie Leist

- Alden Minnick

- Don O'Neill

General

Characteristics of the OBC

The OBC measured 18.9"(H)×14.5"(W)×12.75"(D), and weighed 58.98

pounds. OBC power was supplied by the IGS Power Supply, which

was itself powered from the spacecraft's main +28VDC bus or (for

very brief main-power outages or brownouts) the Auxiliary Computer

Power Unit (ACPU). The OBC required various voltages

(+27.2VDC, +9.3VDC -27.2VDC, +20VDC, +28VDC, and 26VAC, but the

existing documentation is inconsistent on the exact voltages used),

and itself supplied the MDIU (+25VDC, -25VDC +8VDC) and these latter

three voltages were what was actually used internally by the OBC

itself.

The computing characteristics were:

- 39 bits per memory word. Each memory word comprised

three "syllables" (syllable 0, syllable 1, and syllable 2) of 13

bits each.

- 4096 words of memory, in a ferrite core array. All of

this RAM was writable—i.e., there was no read-only memory—but

the readout of the memory was non-destructive.

- The memory was logically divided into 16 "sectors" of 256

words each.

- At any given time only 2 sectors are actually accessible, the

current sector (selectable under program control) and the

"residual" sector (sector 17 octal).

- The third syllables of memory words were writable by the OBC

hardware, but this function was disabled after the spacecraft

left the hangar, so at that point the 3rd syllables were

effectively read-only. Consequently, data words always

needed to be placed into the first two syllables of memory

words. The addressing of data by CPU instructions enforced

this data alignment anyway.

- "Instruction words" were 13 bits each, and "data words" were

26 bits each, so any given memory word could have had a data

word and/or several instruction words packed into it.

There were also provisions for "short" data words of 13 bits,

but these short data words could be used only for testing

purposes by Aerospace

Ground Equipment (AGE), and so were irrelevant for

software.

- Integer arithmetic was 2's-complement.

- Instruction cycle time was 140 μs and all instructions

required a single cycle except for MLT and DIV.

Layout

of Memory Words

I should make it clear that in this section I'm describing my

perspective on the organization of OBC memory, in terms of how the

original OBC programmers would have worked with it, in terms of how

one would work with it using the tools I've created for this site,

and in terms of what I think would be the thinking of "modern"

programmers at the time I'm writing these words (2011). I'm

not slavishly reproducing here the material on memory organization

from the most-complete documentation available to us, namely the

"Guidance and Control" sections (Section VIII) of the Project Gemini Familiarization Manual,

Volume 1 and Volume 2, because

that documentation seems to me to conflict with what I've been told

by actual OBC programmers. The specific area of difficulty is

bit-ordering within memory words. You see, the memory was

accessed by a kind of serial interface, and the natural hardware

view is in terms of the time-order in which the bits are shifted in

and out ... whereas the natural software or mathematical view is in

terms of which bits are the most-significant or least-significant—or

as normally represented, which bits are on the "left" and which are

on the "right". So I'll adopt the latter perspective, but if

you wish to explore what the documentation says on the topic of

bit-ordering, feel free to do so.

In all cases, when I show you binary or octal representations of OBC

memory, it will use the notation common today, in which the

least-significant bits or octal digits are on the right and the

most-significant bits or octal digits are on the left.

As mentioned earlier, memory words are 39 bits, comprising three

13-bit "syllables". In most ways, the syllable is really the

natural memory unit, and not the word. Except in one specific

case, storing and retrieving 26-bit data, syllables within a memory

word are completely unrelated to (and independent of) each

other. So you're really best served by thinking of memory as a

set of syllables rather than a set of words.

Not all syllables are created equal. In the normal operating

mode of the OBC at mission time, the following rules apply:

- All CPU instructions which fetch, store, or otherwise operate

on data stored in memory work only

with 26-bit (2-syllable) data words in which the

less-significant syllable is stored in syllable 0 of memory and

the more-significant word is stored in syllable 1 (in the same

word) of memory.

- Only syllables 0 and 1 are capable of being modified.

Syllable 2 is read-only.

- Therefore, as you can imagine, all data other than code is

allocated in syllables 0 and 1.

- Code is commonly stored in syllable 2 ... though since data

does not use all of syllables 0 and 1, some code will be stored

in syllables 0 and 1 as well.

(There's also a less-common operating mode called "half-word mode"

which has somewhat different rules, but this mode has limited usage

so we'll return to it later rather than diverting the main

discussion.)

Now let's look at some common syllable or double-syllable formats.

Every CPU instruction consists of a single syllable, in the

following bit layout:

PPPPAAAAAAAAA

where PPPP

is a 4-bit code identifying the specific CPU instruction (the "op

code") and AAAAAAAAA is a 9-bit code (3 octal

digits) identifying (in a way that varies by instruction type) the

operand for the instruction. Conventionally, OBC programmers

name the individual bits like so:

- OP4

is the most-significant bit of PPPP and OP1

is the least-significant.

- A9

is the most-significant bit of AAAAAAAAA and A1

is the least-significant.

In most instruction types, A1-A8 select a particular memory

word. Since there are only 8 bits, only 256 different words

are accessible. Recall, moreover, that memory consists of 16

sectors of 256 words each of 3 syllables each. So the

instruction is able to select a specific word address, but the

sector containing the word and the syllable within the word can't be

selected ... those have to be known by other means, which we'll

discuss later; for now, just realize that at any time there's some

"current sector" and "current syllable", and that whatever the CPU

is doing operates within that current selection. When A1-A8

is interpreted in this way, A9 can be used to override the

current sector and instead to do a one-time selection of sector 0,

which is referred to as the "residual sector". A9=0

means to use the current sector and A9=1 means to use the

residual sector. But there's no way to select a different

sector or a different syllable on an individual-instruction basis.

Several instructions use a scheme in which the field consisting of

bits A1-A3

is given the name "X" and A4-A6 are given the name "Y", thus

giving the instruction two independent parameters. In those

cases, A7

and A8

are unused, and A9 may or may supply additional

functionality

For normal 26-bit data, recall that a standard 2's-complement format

is used. OBC programmers conventionally refer to the sign bit

(i.e., the most-significant bit if interpreting the data as an

unsigned integer) as S, to the most-significant non-sign

bit as M25,

and to the least-significant bit as M1. Therefore, in a word

containing such data, syllable 1 will contain S and M25-M14;

syllable 0 will contain M13-M1.

Numerical data can be interpreted in two different ways, depending

on the interpretation of the software. Obviously, the data

could be interpreted as a simple 2's complement integer. It

can also be interpreted as a fractional value with absolute value

less than 1.0. In the latter interpretation, there is some

scaling factor needed to relate the actual value of the number to

the binary value that's stored in memory. The OBC and its software

have no method for dealing with scaling factors, and it was up to

the programmer to understand which interpretation was used, as well

as to explicitly scale values during computations to avoid overflow

and loss of significant bits.

An important variation in which 26 bits of data aren't numerical in

nature is the so-called "HOP constant". A "HOP constant" is

used by a dedicated CPU instruction (HOP) to change things

such as the currently-selected memory sector and syllable by loading

a hidden CPU register that can't be accessed by other means. The

layout of a HOP constant is as follows:

xxxxxxxxHxSSxPPPPAAAAAAAAA

In this scheme:

- Bits AAAAAAAAA are given names A9-A1

and are interpreted as described earlier, in that they allow

selection of a word address (0-255) and provide an override for

current-sector vs. residual sector. After the HOP

instruction executes, this setting persists within the CPU's

hidden HOP register only for the current instruction and is then

incremented to the next sequential word (or to some other word

if a branch occurs).

- Bits SS, respectively given the

names SYB

and SYA,

specify

the current syllable: 00 for syllable 0, 01 for syllable

1, and 10 for syllable 2. After the HOP

instruction executes, this setting persists until another HOP

instruction changes it.

- Bits PPPP, respectively given the

names S4-S1,

specify the current sector. After the HOP

instruction executes, this setting persists until another HOP

instruction changes it, though as we've seen it can be

overridden to instead use sector 0 on an

instruction-by-instruction basis using the A9

feature possessed by some of the CPU instructions.

- H

selects between "normal" mode (H=0) and "half-word" mode (H=1),

and this mode persists until another HOP instruction changes

it. "Normal" mode is what I've been describing to you up

to this point. In half-word mode (HWM), the data comes

from syllable 2 rather than syllables 0,1, and therefore

is only 13 bits rather than 26. When the CPU fetches such

data from memory, it fills the least-significant 13 bits of the

CPU's accumulator register, while the most-significant 13-bits

are all 0. An interesting consequence of being in the

half-word mode is that any

HOP

instruction will return to normal mode (since H

is among the higher 13 bits of a HOP constant) and the current

syllable will always become 0 (since SYB and SYA

are also among the 13 more-significant bits). Moreover,

since the the OBC's ability to write to syllable 2 is disabled

after the spacecraft has left the hangar, no STO

or SPQ

have any effect in half-word mode.

- At power-up, the behavior differed between the early Gemini

missions without ATM (Auxiliary Tape Memory), and the later ones

with ATM:

- Without ATM, it is as if a HOP constant is loaded that puts

the unit in normal mode (i.e., not half-word mode) at syllable

0 of word 0 in sector 0.

- With ATM, it is as if a HOP constant is loaded that puts the

unit into half-word mode at syllable 2 of word 0 in sector 0.

You may wonder what half-word mode is good for? Well,

originally, it seems to have been intended for testing

purposes. Later, when the flight-program outstripped the size

of available memory, it became necessary to add the ATM and use it

to overlay programs at runtime. In that case, I guess, it's

useful to be able to run a program entirely within syllable 2 (which

is read-only) without fear that the ATM can overlay it. But

you know, I'm not really sure.

Instruction

Sequencing

You may naïvely suppose (I did!) if you did not read the preceding

section in great detail, that the everyday usage of the words "word"

and "syllable" applies similarly in stepping through the OBC

instructions. In proceeding through a sentence of natural

language like English, you use up all of the syllables in a word

before proceeding to the next word. So you might suppose that

OBC instructions would sequence in a manner something like the

following: word N syllable 0, word N syllable 1, word N syllable 2, word N+1 syllable 0, word N+1 syllable 1, and so

on. In fact, this is not the case at all, and (as you may

infer from the instruction definitions in the following section)

would have caused insuperable difficulties. So get the naïve

interpretation right out of your head!

Instead, the instruction

sequencing was like this:

word 0 syllable N

word 1 syllable N

word 2 syllable N

etc.

so that the syllable number never changed automatically as you

progressed through the program. But you could always change

the syllable manually by executing an instruction (HOP)

and

a HOP constant specifically designed to change the syllable

number.

In retrospect, from an outsiders point of view, it would perhaps

have been less confusing in terms of instruction sequencing if the

OBC hardware designers had used the word "paragraph" rather than

"syllable". Alas! it's a bit late to worry about that

now. The OBC programmers I've consulted seem to think that

this is a perfectly natural scheme, and don't seem to have

experienced any confusion over the concept of "syllables".

CPU

Instructions

If you're interested in Gemini, you may not be very interested in

Apollo's LVDC instruction

set. But there are so many similarities between the two that

I'll probably not be able to resist the temptation to point out some

of the differences as I proceed. A difference not pointed out

in the table below is that the LVDC instructions MPH, XOR,

and CDS,

EXM

are not present in the OBC.

Note that in what follows, a name representing a location of memory

holding an instruction is called a "left-hand symbol" in the

parlance of the Gemini OBC programmers, and I will continue to call

it that (or LHS for short) rather than adopting more-current

terminology.

Finally, when I talk below about the assembly-language syntax of the

instructions, I'm referring to the syntax supported by my own yaASM assembler presented as a

download on this website. This syntax is very similar to the

original OBC assembler's syntax but we can't be sure it's identical

because no documentation for the original assembler has been located

up to this point in time.

Mnemonic

|

Opcode

(OP1-OP4)

in octal

|

Timing

(140 μs

cycles)

|

Description of the instruction

|

HOP

|

00

|

1

|

This instruction combines

an unconditional jump instruction with various other

configuration options, such as memory-sector

selection. The way it works is that the address A1-A9

points to a memory word that contains a "HOP constant", and

the HOP instruction transfers

that HOP constant into the HOP register. Recall that

A1-A8 select the offset within a 256-word sector, and A9 is

the "residual bit" that selects between the current sector

and the "residual sector". There is no provision for a

partial HOP constant, and the full HOP constant needs to be

given every time a HOP instruction is

used. See also TRA.

However ... the fact that HOP operates on HOP

constants rather than on the left-hand symbols that are the

labels for locations in the code as actually understood by

the programmers, is not very convenient. The simple

act of HOPping to a location would have to look something

like this:

HTARGET HOPC

TARGET # Set up a HOP

constant for the target location.

...

HOP HTARGET # HOP to

the target location

...

TARGET

...

#

Location we want to HOP to.

This is pretty cumbersome. The assembler therefore

provides a special feature in that if the operand of a HOP

is a left-hand symbol for a code location, which would

otherwise be illegal, the assembler silently allocates and

initializes a HOP constant of the same name, but enclosed in

parentheses, and then it pretends that the operand of the

HOP was really the newly-created HOP constant.

Therefore, in assembly language, the following becomes legal

even though seemingly illegal in machine code:

HOP TARGET #

HOP to the target location

...

TARGET

...

#

Location we want to HOP to.

But what the assembler really outputs in this case is the

same as in the first example (with the HOP constant named "(TARGET)"

instead of "HTARGET").

The assembler performs a similar service for the CLA

and STO instructions (see

below). There are some drawbacks to this special feature as

well, namely:

- Any left-hand symbols used as targets of HOPs in this

way must be 6 characters or less rather than 8.

- The assembler always creates the implicit HOP

constants in the residual sector 17, syllable 0.

- Since there are no explicit allocations for the

implicit HOP constants, it's easy for the programmer to

overlook that they're being created, and therefore to be

less aware of the rate at which memory is being used up.

- There's no provision for half-word mode.

Fortunately, there's no drawback here that can't be worked

around by explicitly defining any troublesome HOP constants

needed, as in the first example.

|

DIV

|

01

|

1

(results

available

after 6)

|

This is the division

instruction. The contents of the accumulator are

divided by the operand pointed to by the address A1-A9

embedded within the instruction to produce a 24-bit

quotient. Recall that A1-A8 select the offset within a

256-word sector, and A9 is the "residual bit" that selects

between the current sector and the "residual sector".

The quotient is available via the SPQ instruction

from the 5th instruction following the DIV.

In

other words, 4 other instructions not involving

multiplication or division can be performed in the interval

between DIV and SPQ.

To illustrate the assembly-language syntax, let's divide the

integer 56 by 3 and store the result in a variable:

RESULT

#

Allocate variable for output.

K56

DEC

56 # Provide

dividend as a constant.

K3

DEC

3 #

Provide divisor as a constant.

CLA

K56 # Load divisor

into accumulator.

DIV

K3 # Start the

division.

NOP

#

The result won't be available

NOP

#

for a while, so kill some time.

NOP

NOP

SPQ

#

Fetch quotient into accumulator.

STO RESULT #

Save it!

|

PRO

|

02

|

1

|

Inputs or outputs an i/o

"signal" into or from the accumulator. (In the AGC

these are called "channels". In current terminology,

we'd probably usually refer to them as "ports".)

Whether or not an input or an output is performed depends on

the particular signal chosen. The X (A1-A3) and Y

(A4-A6) operand fields are used for signal selection.

A9 is used as well. For an output operation, it

determines if the accumulator should be cleared after the

output (A9=1) or preserved (A9=0). For an input

operation, it determines if the data should be loaded into

the accumulator (A9=1) or logically OR'd with the

accumulator (A9=0). A table of the i/o signals vs.

addresses is given in the following section.

(The PRO instruction is

essentially equivalent to the LVDC PIO

instruction, but the selection of i/o signals is different.)

The documentation does not explain this, but I think that

when the PRO instruction is

accessing a single-bit signal, only the accumulator's sign

bit is used as the output or the input. (I'm not sure

what the effect on other bit-positions should be on input.)

There are several allowable assembly-language syntaxes for

this instruction:

PRO YX # If

A9=0

PRO

0YX #

Same as "PRO YX"

PRO

4YX

# If A9=1

(Or, you could just look at it as having a literal octal

constant as operand, and that constant was placed directly

into the bits A9-A1.) For example, to read MDIU

keystroke data, X=3

and Y=4, so

PRO 43

|

RSU

|

03

|

1

|

Same as SUB (see below),

except that the order of the operands in the subtraction is

reversed.

Assembly-language example to compute RESULT=3-56:

RESULT

#

Allocate variable for output.

ARG1 DEC

56

ARG2 DEC 3

CLA ARG1

RSU

ARG2

STO RESULT

|

ADD

|

04

|

1

|

Adds the contents of the

accumulator with the contents of the address embedded within

the instruction and places the result in the

accumulator. Recall that A1-A8 select the offset

within a 256-word sector, and A9 is the "residual bit" that

selects between the current sector and the "residual

sector".

Assembly-language example to compute RESULT=56+3:

RESULT

#

Allocate variable for output.

ARG1 DEC

56

ARG2 DEC 3

CLA ARG1

ADD

ARG2

STO RESULT

|

SUB

|

05

|

1

|

Subtracts the contents of

a word pointed to by the address embedded within the

instruction from the accumulator, and puts the result back

into the accumulator. Recall that A1-A8 select the

offset within a 256-word sector, and A9 is the "residual

bit" that selects between the current sector and the

"residual sector". See also RSU.

Assembly-language example to compute RESULT=56-3:

RESULT

#

Allocate variable for output.

ARG1 DEC

56

ARG2 DEC 3

CLA ARG1

SUB

ARG2

STO RESULT

|

CLA

|

06

|

1

|

Store a value to the

accumulator, from the memory word at the address embedded

within the instruction. Recall that A1-A8 select

the offset within a 256-word sector, and A9 is the "residual

bit" that selects between the current sector and the

"residual sector".

Assembly-language example to load the accumulator with

decimal 56:

K56

DEC 56

CLA

K56

Note that as with the HOP instruction, the

assembler allows seemingly meaningless usages like "CLA

LHS", where LHS is the left-hand symbol

of a code location rather that the name of a variable or

constant. What the assembler does in this case is

automatically, silently to create a HOP constant in memory

called "(LHS)", and then to

substitute the "CLA (LHS)" for the original

instruction. See the notes accompanying the HOP

instruction for full details.

|

AND

|

07

|

1

|

Logically ANDs the

contents of the accumulator with the contents of the address

embedded within the instruction and places the result in the

accumulator. Recall that A1-A8 select the offset

within a 256-word sector, and A9 is the "residual bit" that

selects between the current sector and the "residual

sector".

Assembly-language example to compute RESULT=037&052

(i.e.,

to logically AND together octal 37 and octal 52):

RESULT

#

Allocate variable for output.

ARG1 OCT 37

ARG2 OCT 52

CLA ARG1

SUB

ARG2

STO RESULT

|

MPY

|

10

|

1

(results

available after 3)

|

This is a multiplication

instruction. It multiplies two 24-bit numbers to

produce a 26-bit product. The accumulator provides the

address of one multiplication factor, and the address

embedded in the instruction points to the other

factor. Recall that A1-A8 select the offset within a

256-word sector, and A9 is the "residual bit" that selects

between the current sector and the "residual sector".

In both cases, the most-significant 24-bits of the operands

are used, and the least-significant 2 bits of the operand

are ignored. The result is available via the SPQ instruction on

the 2nd instruction following MPY. Any

other instruction not involving multiplication or division

can be performed between the MPY and the SPQ.

To illustrate the assembly-language syntax, let's multiply

the integer 56 by 3 and store the result in a variable:

RESULT

#

Allocate variable for output.

K56

DEC 56

K3

DEC 3

CLA K56

MPY

K3 # Start the

multiplication.

NOP

#

The result won't be available

NOP

#

for a while, so kill some time.

SPQ

#

Fetch product into accumulator.

STO RESULT #

Save it!

|

TRA

|

11

|

1

|

This is an unconditional

jump instruction, which branches to the address embedded in

the instruction. Bits A1-A9 of the embedded address

represent the new offset within either the

currently-selected sector or the residual sector. Note

that the syllable remains the same, so if (for example) the

TRA is itself in syllable 1 of the current program counter,

then the next instruction executed will be at syllable 1 in

the new program counter. (This differs from the

behavior of the corresponding LVDC instruction, in

that the LVDC instruction allows selection of the target

syllable via A9, but does not allow the new program counter

to be in the residual sector.)

See also the description of shorthands

for

various instructions.

Assembly-language examples:

# Branch from location

START to location FINISH.

START TRA

FINISH

...

FINISH

...

# Branch from location START2 to FINISH2, but use

# relative addressing rather than the left-hand

# symbol FINISH2. The NOP instructions below

# could be anything --- the point is simply that

# FINISH2 is 3 words in memory after START2.

START2 TRA *+3

NOP

NOP

FINISH2 ...

The operand for TRA is either an existing

left-hand symbol for an instruction (rather than for a

variable or constant), or else an expression of the form "*+N" or "*-N", where N is any number from 1

to 7.

|

SHF

|

12

|

|

Performs a logical shift

operation on the accumulator. For this instruction,

only bits A1-6 are actually used, as follows:

X

(A1-3)

|

Y

(A4-6)

|

Description of operation

|

1

|

2

|

Shift "right" one

position

|

0

|

2

|

Shift "right" two

positions |

X

|

3

|

Shift "left" one

position |

X

|

4

|

Shift "left" two

positions |

(Other)

|

Clears the

accumulator

|

But what do "left" and "right" mean? Fortunately,

"left" implies multiplication by powers of two, and "right"

division by powers of two, just as modern programmers are

accustomed to.

For the left-shifts, 0 is shifted into the least-significant

bit at the right. For the right-shifts, the sign-bit

is duplicated into the most-significant bit at the left.

For illegal X,Y combinations, the accumulator is zeroed.

Note that this instruction is similar to the corresponding LVDC instruction,

but differs in details.

See also the description of shorthands

for

various instructions.

There assembly-language syntax for this instruction is:

SHF YX

(Or, you could just look at it as having a literal octal

constant as operand, and that constant was placed directly

into the bits A6-A1.) For example, to shift right one

position, X=1 and

Y=2, so

SHF 21

|

TMI

|

13

|

1

|

This is a conditional

jump instruction, which branches to the address embedded in

the instruction if the accumulator is less than zero, but

simply continues to the next instruction in sequence if the

accumulator greater than or equal to zero. Bits A1-A9

of the embedded address represent the new offset within the

currently selected 256-word instruction sector or the

residual sector. See also TNZ. (This

differs from the behavior of the corresponding LVDC instruction, in

that the LVDC instruction allows selection of the target

syllable via A9, but does not allow the new program counter

to be in the residual sector.)

Assembly-language examples:

# Branch from location

START to location FINISH

# because VALUE is negative:

VALUE DEC -129

START TMI FINISH

...

#

Never gets here!

FINISH

...

#

But does get to here!

# Don't branch from START2 to FINISH2, because

# VALUE2 is not negative:

VALUE2 DEC 127

START2 TMI FINISH2

...

#

Comes to here!

TRA BAILOUT

FINISH2

...

#

Never comes to here!

BAILOUT ...

The operand for TMI is either an existing

left-hand symbol for an instruction (rather than for a

variable or constant), or else an expression of the form "*+N" or "*-N", where N is any number from 1

to 7. The usage of the latter relative-addressing

forms isn't illustrated in the code example for TMI,

but you can look at the code example for TRA

instead; it works exactly the same for TMI.

|

STO

|

14

|

1

|

Stores the contents of

the accumulator in the word indicated by the address

embedded within the instruction. Recall that A1-A8

select the offset within a 256-word sector, and A9 is the

"residual bit" that selects between the current sector and

the "residual sector". The accumulator retains

its value.

Assembly-language example:

RESULT

#

Allocate a variable

STO

RESULT # Store accumulator value in the

variable.

Note that as with the HOP instruction, the

assembler allows seemingly meaningless usages like "STO

LHS", where LHS is the left-hand symbol

of a code location rather that the name of a variable or

constant. What the assembler does in this case is

automatically, silently to create a HOP constant in memory

called "(LHS)", and then to

substitute the "STO (LHS)" for the original

instruction. See the notes accompanying the HOP

instruction for full details.

|

SPQ

|

15

|

1

|

Store a product or

quotient (computed with MPY or DIV)

into the word indicated by the address embedded within the

instruction. Recall that A1-A8 select the offset

within a 256-word sector, and A9 is the "residual bit" that

selects between the current sector and the "residual

sector". The accumulator retains its

value. (This instruction is somewhat similar to the LVDC instruction CLA

0775, though quite different in detail.)

For assembly-language examples, see MPY

or DIV above.

|

CLD

|

16

|

1

|

A discrete input (i.e., a

single bit) selected by the operand address is read into the

accumulator. The entire accumulator is overwritten so

that every bit position has the value of the discrete input

bit, and consequently will be either 000000000 or else

377777777 octal. A test of either TMI

or TNZ thereafter can thus

branch on the basis of the bit value. A table of the

allowed discrete inputs follows later. (This

instruction does not exist in the LVDC.)

See also the description of shorthands

for

various instructions.

There assembly-language syntax for this instruction is:

CLD YX

(Or, you could just look at it as having a literal octal

constant as operand, and that constant was placed directly

into the bits A6-A1.) For example, to read the MDIU

data-ready bit, X=1

and Y=0, so

CLD 01

|

| TNZ |

17

|

1

|

This is a conditional

jump instruction, which branches to the address embedded in

the instruction if the accumulator is not zero, but simply

continues to the next instruction in sequence if the

accumulator is zero. Bits A1-A8 of the embedded

address represent the new word address within the sector,

while bit A9 selects between the current sector vs. the

residual sector. (In the LVDC, A9 instead selects the

syllable within the current sector, which is possible since

the LVDC has only 2 syllables.) See also TMI.

Assembly-language examples:

# Example 1: Branch to

location IS129 if accumulator is

# equal to 129 and to ISNOT129 if accumulator is not

# equal to 129:

K129 DEC 129

SUB K129

TNZ

ISNOT129

TRA IS129

...

IS129 ...

...

ISNOT129 ...

# Example 2: A simple loop with 10 iterations:

LOOPCTR

#

Variable for counting loop iterations.

K1

DEC 1

K10

DEC 10

CLA

K10 # Setup for the

loop.

STO LOOPCTR

LOOP

...

#

Do stuff

CLA LOOPCTR #

Decrement and test loop counter

SUB K1

TNZ LOOP

...

#

Done!

The operand for TNZ is either an existing

left-hand symbol for an instruction (rather than for a

variable or constant), or else an expression of the form "*+N" or "*-N", where N is any number from 1

to 7. The usage of the latter relative-addressing

forms isn't illustrated in the code example for TNZ,

but you can look at the code example for TRA

instead; it works exactly the same for TNZ.

|

I/O Signals (For PRO

Instruction)

Note that in assembly language, in the operand for a PRO

instruction, the Y operand field would proceed the X operand

field. So, for example, if X=3 and Y=4, the instruction would

be PRO43.

That's

the opposite of present ordering of the columns in the table below

and could be confusing, for which I apologize, but I'm too lazy to

completely rewrite the table.

Operand

|

Input /

Output

|

Signal

|

Comment

|

X

(A1-A3)

|

Y

(A4-A6)

|

0

|

0

|

In

|

Digital

Command System shift pulse gate

|

Causes a 24-bit word

buffered in the Digital Command System

(DCS) to be read into bits M1-M24 of the accumulator.

Or, reads data from the Rendezvous

Radar (if any).

|

0

|

1

|

Out

|

Data

Transmission System control gate

|

Used to output a data word

to the Instrumentation System (IS)

for digital downlink.

|

0

|

2

|

In/Out

|

Time

Reference System data and timing pulses

|

The action of this signal

seems pretty complex. Please read the section on the Time Reference System

(TRS) for my conclusions as to what it's actually supposed

to do.

|

0

|

3

|

Out

|

Digit

magnitude weight 1

|

Used in conjunction with

"Digit magnitude weight 2", "Digit magnitude weight 4", and

"Digit magnitude weight 8" to write a particular digit to an

MDR position

previously selected using the "Digit select weight X" outputs. The

weights derive from a BCD value of the digit whose display

is desired.

I haven't seen any explanation of how to clear a digit so

that it's blank ... perhaps there was no such feature,

though it seems to me that it would make data-entry very

confusing if so. There are a number of ways this might

have been done. Until I understand it better, the yaPanel MDIU emulator

handles this as follows:

- Using any combination of magnitudes that doesn't form

a BCD (i.e., something in the range 0-9) will clear the

selected digit to be blank.

- Pressing the MDR's CLEAR button will make all of the

digits blank.

|

0

|

4

|

Out

|

Reset

data ready, enter, and readout

|

When zeroed, signals the MDIU to reset its

internal buffer so that a numerical keystroke subsequently

be collected. It is unclear if this needs to be

returned to a non-zero state later. The CLD

inputs associated with the ENTER and READ OUT keys also are

cleared as a result.

|

0

|

5

|

Out

|

Digit

select weight 1

|

Used in conjunction with

"Digit select weight 2" and "Digit select weight 4" to

select the next digit position to which a display value will

be output to the MDIU.

It is not really explained how these work, but I think that

they are used to form an index from 0-7 in the obvious way,

and that the leftmost address digit is 0, the 2nd address

digit is 1, the leftmost message digit is 2, and so on. |

0

|

6

|

Out

|

Memory

strobe

|

I believe that this signal

is used only in

conjunction with the AGE for testing

purposes. When the accumulator is negative, it seems

to enable a hardware mode called "marginal early" may help

in determining how robust the memory access is with respect

to marginal timing. When the accumulator is positive

or zero, it disables this diagnostic feature.

|

1

|

0

|

Out

|

Computer ready

|

Signal to the Digital Command System (DCS) that the

OBC wishes to read a buffered uplinked data word. Also

used to tell the Rendezvous

Radar, if any, that radar data is required. In

the latter case, a 20 ms. delay must occur afterward before

polling the radar-ready discrete input (CLD00).

|

1

|

1

|

Out

|

Drive

counters to zero

|

For setting a delta-V

display on the IVI to zero. First

do PRO11 with the accumulator

negative, then (see "Select X counter") select the X, Y, or

Z axis, then do PRO11 with the accumulator

positive or zero to return to the normal state. CLD31,

CLD25,

and CLD26 can be subsequently

used for feedback that the displays are actually at zero.

|

1

|

2

|

Out

|

Enter

|

When inactive, the Time Reference System

(TRS) is capable of receiving timing data (like TR

or TX) from the ODC. When

active, the ODC can receive timing data (like ET or TR)

from the TRS. |

1

|

3

|

Out

|

Digit

magnitude weight 2

|

See Digit magnitude

weight 1

|

1

|

4

|

Out

|

Display

device drive

|

The "display device

drive", as far as I can see, is what's used to turn the

physical wheel on which the MDIU

display-digits are inscribed to the proper position for

display. In other words when the drive is off (i.e.,

PRO41 output a zero) the last-selected digit continues to be

displayed, while when the drive is on (PRO41 output

non-zero) the display wheel will be turned if

necessary. Therefore, the drive is normally off, but

is turned on briefly when a digit is being changed.

The full procedure is as follows:

- Use the digit-select weights to choose the

display-position which is supposed to be changed.

- Turn on the display device drive.

- Use the digit-magnitude weights to determine what

digit is driven into the selected display position.

- Wait 0.5 seconds.

- Turn off the display device drive.

|

1

|

5

|

Out

|

Digit

select weight 2

|

See Digit select weight 1

|

1

|

6

|

|

Autopilot scale factor

|

|

2

|

0

|

Out

|

Pitch

resolution

|

Controls the range switch

for Pitch Error (or down range error) output. If the

sign bit is positive, then there is a 6-to-1 attenuation

applied; if the sign bit is negative, there is no

attenuation.

|

2

|

1

|

Out

|

Select

X counter

|

Used along with "Select Y

counter" to select one of the IVI's

delta-V displays to receive additional commands, as follows:

- X-axis: PRO12 with accumulator

negative, PRO13 with accumulator

positive or zero.

- Y-axis: PRO12 with accumulator

positive or zero, PRO13 with accumulator

negative.

- Z-axis: PRO12 with accumulator

negative, PRO13 with accumulator

negative.

|

2

|

2

|

Out

|

Aerospace Ground Equipment data link

|

For outputting a single

data bit to the dedicated AGE data link.

|

2

|

3

|

Out

|

Digit

magnitude weight 4

|

See Digit magnitude

weight 1 |

2

|

5

|

Out

|

Digit

select weight 4

|

See Digit select weight 1

|

2

|

6

|

In

|

Reset

start computation

|

From the PCDP's

RESET switch.

|

3

|

0

|

Out

|

Yaw

resolution

|

Controls the range switch

for Yaw Error (or cross-range error) output. If the

sign bit is positive, then there is a 6-to-1 attenuation

applied; if the sign bit is negative, there is no

attenuation. |

3

|

1

|

Out

|

Select

Y counter

|

See "Select X counter".

|

3

|

2

|

Out

|

Aerospace Ground Equipment data clock

|

Provides a data clock, one

pulse at a time, for reading data on the dedicated AGE data link.

|

3

|

3

|

Out

|

Digit

magnitude weight 8

|

See Digit magnitude weight

1

|

3

|

4

|

In

|

Read

Manual Data Insertion Unit insert data

|

Reads a keystroke that has

been buffered in the MDIU.

This operation should be done only in response to a separate

discrete "Data ready" input via CLD. The BCD

value of the digit is stored into bits M1-M4 of the

accumulator. A PRO40 should be performed

afterward to clear the MDIU buffer and allow the next

keystroke to be collected, and additional PRO

instructions should be used to display the digit on the

MDIU.

|

3

|

6

|

Out

|

Reset

radar ready

|

Sent to the Rendezvous Radar, if any, to

reset its discrete input buffer.

|

4

|

0

|

Out

|

Roll

resolution

|

Controls the range switch

for Roll Error output. If the sign bit is positive,

then there is a 6-to-1 attenuation applied; if the sign bit

is negative, there is no attenuation. |

4

|

1

|

Out

|

Elapsed

time control and Time Reference System control reset / ATM

wind-rewind reset

|

Signal to the Time Reference System

(TRS) that the data about to be fetched from the TRS with PRO20

commands is the elapsed time (ET). This output should

persist for 9-15 ms. before being returned to the normal

state. It also apparently acts to reset the TRS

control circuitry.

(Units with ATM only.)

It has additional functionality for the Auxiliary Tape Memory

(ATM), in that it commands the ATM to stop winding or

rewinding. I believe that it also turns off the ATM

ERROR lamp. (I don't know how to select between the

TRS/ATM functions, or if it always performs both

simultaneously.)

|

4

|

3

|

Out

|

Computer malfunction

|

To the PCDP's

MALF light.

|

4

|

4

|

Out

|

ATM

verify/repro command

|

Send a command to the Auxiliary Tape Memory

(ATM) to begin data output. I assume that the

accumulator is negative to begin the output and zero or

positive to end it.

|

4

|

6

|

TBD

|

Second

stage engine cutoff

|

TBD

|

5

|

0

|

Out

|

Computer running

|

To the PCDP's

COMP light.

|

5

|

1

|

In?/Out

|

Time to

start re-entry calculations control / ATM wind command

|

The use for "time to start

re-entry calculations" is TBD.

(Units with ATM only.)

Initiates winding of the ATM.

I assume that the value in the accumulator should be

negative, however, I don't think that outputting a positive

or zero value stops the winding. Instead, use PRO14. (I

don't know how to select between the timing and ATM

functions, or if it always performs both simultaneously.) |

5

|

2

|

Out

|

Time to

reset control / ATM rewind command

|

Signal to the Time Reference System

(TRS) that transfer of time-to-equipment-reset (TX)

data is desired. This output should persist for 9-15

ms. before being returned to the normal state.

(Units with ATM only.)

Initiates rewinding of the ATM.

I assume that the value in the accumulator should be

negative, however, I don't think that outputting a positive

or zero value stops the rewinding. Instead, use PRO14.

(I don't know how to select between the TRS/ATM functions,

or if it always performs both simultaneously.) |

5

|

3

|

Out

|

Write

output processor

|

For incrementally

adjusting the delta-V displays of the IVI.

First, the X, Y, or Z display is selected (see "Select X

counter" above). No more than 1 ms. later, PRO35

is used to begin the update. The value in the

accumulator comprises the sign bit and M1-M12, so the

maximum change is -4096 to +4095. Since the displays

are actually -999 to +999, in theory the adjustment range is

more than full. In practice, only very small

adjustments would be made. My understanding of what

the hardware actually does is to increment or decrement the

displays by 1 every 21.5 ms., and that it will not be ready

to process another delta-V until the count has reached

zero. For example, trying to change the display by 25

would take about half a second, and no other outputs to the

IVI should take place in that interval. The "Velocity

error count not zero" discrete (CLD22) can be

polled to determine when the increment/decrement pulses have

all been sent to the display and the counter has reached

zero. |

5

|

4

|

In

|

Read

delta velocity

|

This port is used to read

the change in velocity from the platform electronics, and to

zero the reference velocity for the next readings.

A single PRO45 instruction reads the

ΔV from all three

axes into the accumulator. Documentation is unclear as

to how the data appearing in the accumulator is packed, but

my nearest guess as to what it's trying to tell us is that

each of the X, Y, and Z axis readings is a 4-bit

2's-complement value (thus being in the range -8 to +7), and

that they are packed into the accumulator as follows:

XXXXYYYYZZZZ00000000000000

Even if correct, the units are TBD. |

5

|

5

|

TBD

|

Input

processor time

|

TBD

|

5

|

6

|

Out

|

Time to

retrofire control

|

Signal to the Time Reference System

(TRS) that transfer of time-to-retrograde (TR)

data is desired. This output should persist for 9-15

ms. before being returned to the normal state. |

6

|

3

|

In

|

Read

pitch gimbal

|

These ports

are used for reading gimbal angles from the inertial

platform. The units used are TBD, as the documents

discussing them speak only of phase-shifted 400 cps voltages

rather than true angles.

15-bit values are provided, including the sign bit and the

14 most-significant bits. The 11 least-significant

bits are zeroed. Each of the PRO

commands associated with these ports both reads a

previously-measured value and begins accumulating a new

measurement, so these ports must be accessed in a very

specific procedure to get a complete set of readings, as

follows:

... at least 5 ms. from

last read of gimbals ...

PRO36 # Must ignore the first value

received.

... wait >= 5 ms. ...

PRO46

STO PITCH

... wait >= 5 ms. ...

PRO56

STO ROLL

... wait >= 5 ms. ...

PRO36

STO YAW

# The total time must be <=30 ms.

|

6

|

4

|

In

|

Read

roll gimbal

|

6

|

5

|

In

|

Read yaw

gimbal

|

7

|

0

|

Out

|

Pitch

error command

|

For the

re-entry mode, the outputs are down-range error rather than

pitch error, and cross-range error rather than yaw error.

These are values which are expected to be output at

intervals of 50 ms. or less, and feed into a 7-bit

digital-to-analog converter for driving the Flight Director

Indicator (FDI). The output comes from the accumulator

sign bit and from bit-positions M8-M13. The analog

outputs also feed into range switches which can attenuate

the signals, and are controlled by PRO02,

PRO03,

and PRO04.

|

7

|

1

|

Out

|

Yaw

error command

|

7

|

2

|

Out

|

Roll

error command

|

Discrete Inputs

(For CLD

Instruction)

Note that in assembly language, in the operand for a CLD

instruction, the Y operand field would proceed the X operand

field. So, for example, if X=3 and Y=4, the instruction would

be CLD 43.

That's the opposite of present ordering of the columns in the table

below and could be confusing, for which I apologize, but as I said

above, I'm too lazy to rewrite the table.

Operand

|

Signal

|

Comment

|

X

(A1-A3)

|

Y

(A4-A6)

|

0

|

0

|

Radar

ready

|

Indicates that data from

the Rendezvous Radar (if

any) is ready.

|

0

|

1

|

Computer mode 2

|

From the PCDP's

COMPUTER mode selector rotary dial. The rotary dial

has 7 positions, encoded onto 3 discrete inputs, "Computer

mode 1", "Computer mode 2", and Computer mode 3". The

encoding is:

Computer

Mode 1

|

Computer

Mode 2

|

Computer

Mode 3

|

Mode

|

0

|

0

|

0

|

TBD

|

0

|

0

|

1

|

Pre-launch

|

0

|

1

|

0

|

Ascent

|

0

|

1

|

1

|

Catch-up

|

1

|

0

|

0

|

Rendezvous

|

1

|

0

|

1

|

Re-entry

|

1

|

1

|

0

|

TBD

|

1

|

1

|

1

|

TBD

|

|

0

|

2

|

Spare

|

|

0

|

3

|

Processor timing phase 1

|

|

0

|

4

|

Spare

|

|

1

|

0

|

Data

ready

|

From the MDIU. It

indicates that a digit-keystroke has been buffered within

the MDIU and is ready to be read.

|

1

|

1

|

Computer mode 1

|

See "Computer mode 2". |

1

|

2

|

Start

computation

|

From the PCDP's

START switch

|

1

|

3

|

X zero

indication

|

Indicates that the IVI's X-velocity display is at zero.

|

1

|

4

|

ATM

clock

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section.

|

2

|

0

|

Enter

|

From ENTER key of MDIU

|

2

|

1

|

Instrumentation System sync

|

From Instrumentation

System (IS), to trigger beginning of a new downlink

cycle every 2.4 seconds.

|

2

|

2

|

Velocity error count not zero

|

From the IVI.

It is an indicator that a prior "Write output processor" (PRO35)

has reached completion.

|

2

|

3

|

Aerospace Ground Equipment request

|

From the AGE.

Becomes active (accumulator negative) when a word is

available on the dedicated AGE data link.

|

2

|

4

|

Spare

|

|

3

|

0

|

Readout

|

From READ OUT key of MDIU

|

3

|

1

|

Computer mode 3

|

See "Computer mode 2". |

3

|

2

|

Spare

|

|

3

|

3

|

ATM on

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

3

|

4

|

ATM data

channel 2

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

4

|

0

|

Clear

|

From CLEAR key of MDIU

|

4

|

1

|

ATM mode

control 1

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

4

|

2

|

Simulation mode command

|

|

4

|

3

|

ATM end

of tape

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

4

|

4

|

ATM data

channel 3

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

5

|

0

|

Time to

start re-entry calculations

|

This is a signal from the

Time Reference System

(TRS) that its TR (time to retrograde) counter

has reached zero.

|

5

|

1

|

ATM mode

control 2

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

5

|

2

|

Y zero

indication

|

Indicates that the IVI's Y-velocity display is at

zero. |

5

|

3

|

ATM data

1

|

(Units with ATM only. Otherwise, spare.)

See the ATM

section. |

5

|

4

|

Spare

|

|

6

|

0

|

Digital

Command System ready

|

This is a signal from the

Digital Command System (DCS)—i.e., the

digital uplink from ground control—that data is available

for the OBC to read. In general, it is expected that

this signal be polled at 50 ms. intervals or shorter. |

6

|

1

|

Fade-in

discrete

|

From the PCDP's

FADE-IN. This is a signal from a relay, but anything

beyond that is TBD.

|

6

|

2

|

Z zero

indication

|

Indicates that the IVI's Z-velocity display is at

zero. |

6

|

3

|

Umbilical disconnect

|

|

6

|

4

|

Spare

|

|

7

|

0

|

Instrumentation System request

|

|

7

|

1

|

Abort