This is a superseded page, so you may want to look instead at the

superseding page instead of this one. On the other

hand ....

At the time the Virtual AGC electronic-simulation framework

and this explanatory page were first written, the simulation

framework was based on the file formats used by the KiCad

5 EDA system. But when KiCad 6 was subsequently

released (the stable version at this writing is 8), those file

formats were replaced by completely-different formats, thus

breaking the Virtual AGC electronic simulations at the same

time. This page relates to those still-available KiCad

5 based files, whereas the superseding page relates to the KiCad

6 (and beyond) simulation framework. This page could

nevertheless remain useful, and hence will be retained.

But this page is essentially a draft that was never perfected,

and therefore has some deficiencies even beyond its limitation to

KiCad 5.

One such deficiency is that setup is never discussed. I

would suggest using the superseding page's setup instructions.

Additionally, you will need to work within the superseded

"schematics-KiCad-5" branch of the Virtual AGC software repository

rather than the "schematics" branch that's advised in superseding

setup. In other words, you need to use schematic-diagram

files in their old formats rather than in their new ones.

Personally, I have both branches of the repository installed on my

computer, in separate folders, to have both available to me

simultaneously. My suggestion would be to install the old

files in a new folder called

"virtualagc-schematics-KiCad-5". Here's how to do that:

git clone --depth=1 -b schematics-KiCad-5 https://github.com/virtualagc/virtualagc.git virtualagc-schematics-KiCad-5

Any instructions that mention a folder such as Schematics/ are

referring to virtualagc-schematics-KiCad-5/Schematics/.

But because the installation instructions asked you to add the

virtualagc-schematics/Scripts/ folder to your PATH, we have a

slight problem with superseded framework, because it uses scripts

of the same names but stored in a different folder, namely

virtualagc-schematics-KiCad-5/Scripts/. In other words,

without further action on our part, we'd be in jeopardy of having

the normal, non-workaround scripts found rather than the KiCad 5

workaround scripts, which wouldn't do at all. To get around

this in Linux or Mac OS, I'd suggest doing this:

cd path/to/virtualagc-schematics-KiCad-5/Schematicsexport PATH=/absolute/path/to/virtualagc-schematics-KiCad-5/Scripts:$PATHcd \path\to\virtualagc-schematics-KiCad-5\Schematicsset PATH=\absolute\path\to\virtualagc-schematics-KiCad-5\Scripts;%PATH%Digital simulation of the AGC electrical design can provide

very-detailed insight into how that electrical design

functions. Aside from satisfying simple personal interest,

this is very valuable if you wish to create a simulation of the

AGC, in the manner of Virtual AGC Project's Block II AGC

software simulator or Block I

AGC software simulator, or John Pultorak's Block

I

AGC hardware simulator, and want to have some way of

verifying that your creation works properly.

Realize, though, that the purpose of these simulations can only

be very accurate examination or verification of behavior. At

the present time, these simulations are very much slower than real

time, so you cannot expect to use them as replacements for the

software simulations of the AGC CPU mentioned in the preceding

paragraph. One day, as computer speeds continue to advance,

perhaps! But not now.

The basic simulation process, from end to end, can be summarized

as follows:

Steps #1, #2, and #3, and creation of a simple test bench for

step #4, have already been accomplished for you by the Virtual AGC

Project. It only remains for you to modify the test bench,

select whichever AGC software you want to run on the simulation,

recompile the simulation, run the simulation, and look at the

results. Developing the test bench is the only tricky part.

Multiple types of simulation are possible, including:

Indeed, if you are capable of writing your own Verilog

descriptions of peripheral hardware in the LM or CM, you can

probably even simulate AGC+DSKY+Other. What we'll

concentrate on discussing, however, is the full AGC.

Hopefully, with that background, you'll be able to see for

yourself how to create and run some other granularity of the

simulation.

One slight point of confusion is that in the AGC design, the

various plug-in circuits are called "modules", while Verilog also

uses the term "modules" for its constructs that are similar to

"functions" or "subroutines" in other programming languages.

Now as it happens, we've implemented the simulation in such a way

that each AGC module actually is modeled as a single

Verilog module. That's more-or-less a coincidence, though,

and if you attempt to work with any simulations that differ from

those we've pre-prepared for you, you may have to watch out for

the dual meaning of this term.

The Virtual AGC Project's

Electro-Mechanical page.

Apollo-era AGC/DSKY electrical-schematic diagrams:

Open-source software:

Mike Stewart's similar transcription + simulation effort:

It should be noted that while the AGC simulations described on

this page were not based on Mike Stewart's pre-existing

project, Mike's simulation was a very important resource in the

sense that cross comparisons of the Mike's implementation with

this one provided a way to detect errors in both implementations

that would not have been easily discoverable otherwise.

The Virtual AGC software repository already contains some

fully-worked out examples of digital simulations. The simplest is

something called "testVerilog", which is actually a small circuit

block from the AGC's circuit module A1, the "scaler" module.

Let's consider the testVerilog simulation, within the context of

steps #1 through #7 outlined in the Introduction

above.

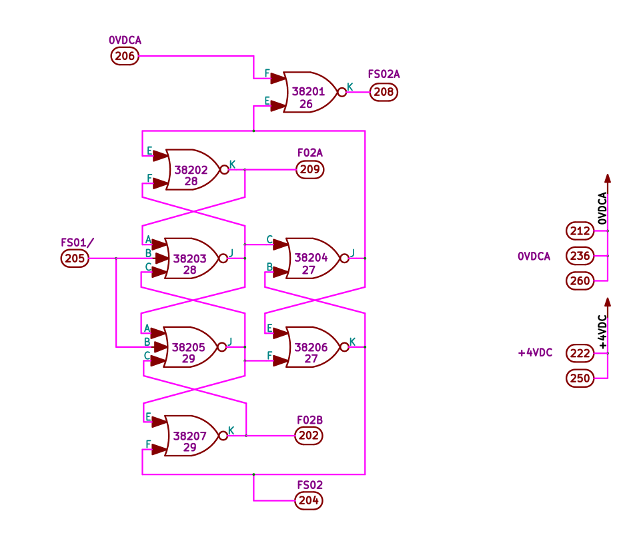

Step #1: Start with the original Apollo Program

schematic-diagram drawing for module A1, which is drawing

2005259A, two sheets (click to enlarge):

Don't be confused by the fact that the inputs of NOR gates in the

circuit are decorated with little triangles that make the gate

look like a rocket ship. They're just regular NOR gates in

spite of that. The numbered oval pads are the inputs from or

outputs to the AGC backplane.

After conversion to CAD, KiCad files for this circuit module are

here,

but for exposition purposes I've printed them out as simple images

as well:

Now, AGC module A1 is the "scaler" circuit. If you want to

read about it in some detail, you can look at section

4-5.3.4

of document ND-1021042, which covers the theory of operation

of this module. The module's purpose is to take clock signal

called FS01/ (a 102.4 KHz square wave), which you can see coming

into the module from the AGC's backplane near the upper left on

the first sheet of the schematic, and to run it through a sequence

of circuit blocks that successively cut the frequency of that

signal in half, as follows, and outputting those slower clocks

back to the AGC's backplane:

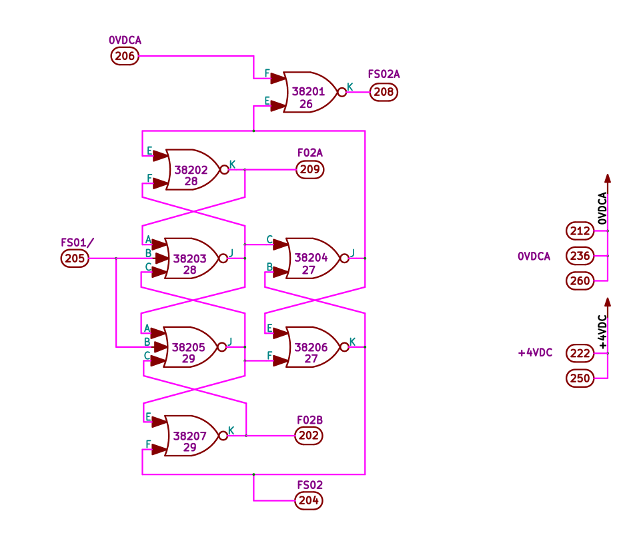

To simplify things, the testVerilog example cuts this all down so

that just the first divide-by-two circuit block, which produces

FS02 from FS01/, is retained in the design. The

CAD

files for testVerilog are here, but here is a simple image

of the circuit:

Step 2: Creation of a netlist from the CAD files. This is

just a feature of the KiCad program itself. While it isn't

terribly instructive, the netlist file for this circuit is

relatively short and relatively readable without any explanation,

so here it is in full:

Step #3: Conversion to Verilog. (You may have noticed that the Introduction mentions that at this point we need to specify the initial state of the flip-flops. If you are an electronics novice it may not be obvious, but to any experienced electronics designer it will have been obvious that the feedback between the pairs of NOR gates in the circuit does indeed create a flip-flop, or at least introduces some kind of memory. For our purposes at the moment, we'll just skip over that point, and note that the repository provides a file called module.init that specifies the initial conditions of the implicit flip-flop. Besides that, another input file called pins.txt is needed, which again, we'll just accept for the moment without further explanation.)

( { EESchema Netlist Version 1.1 created Wed 26 Sep 2018 08:21:48 AM CDT } ( /5D281B38 $noname J2 ConnectorA1-200 ( 202 Net-(J2-Pad202) ) ( 204 Net-(J2-Pad204) ) ( 205 Net-(J2-Pad205) ) ( 206 Net-(J2-Pad206) ) ( 208 Net-(J2-Pad208) ) ( 209 Net-(J2-Pad209) ) ( 212 0VDCA ) ( 222 +4VDC ) ( 236 0VDCA ) ( 250 +4VDC ) ( 260 0VDCA ) ) ( /5D281B3E $noname U126 D3NOR-+4VDC-0VDCA-A_B-E_F ( 6 0VDCA ) ( 7 Net-(U126-Pad7) ) ( 8 Net-(J2-Pad206) ) ( 9 Net-(J2-Pad208) ) ) ( /5D281B45 $noname U128 D3NOR-+4VDC-0VDCA-ABC-E_F ( 1 Net-(U127-Pad2) ) ( 2 Net-(U127-Pad8) ) ( 3 Net-(J2-Pad205) ) ( 4 Net-(J2-Pad209) ) ( 5 0VDCA ) ( 6 0VDCA ) ( 7 Net-(U126-Pad7) ) ( 8 Net-(U127-Pad2) ) ( 9 Net-(J2-Pad209) ) ( 10 +4VDC ) ) ( /5D281B77 $noname U127 D3NOR-+4VDC-0VDCA-B_C-E_F ( 1 Net-(U126-Pad7) ) ( 2 Net-(U127-Pad2) ) ( 3 Net-(J2-Pad204) ) ( 4 0VDCA ) ( 5 0VDCA ) ( 6 0VDCA ) ( 7 Net-(U126-Pad7) ) ( 8 Net-(U127-Pad8) ) ( 9 Net-(J2-Pad204) ) ( 10 +4VDC ) ) ( /5D281B9B $noname U129 D3NOR-+4VDC-0VDCA-ABC-E_F ( 1 Net-(U127-Pad8) ) ( 2 Net-(J2-Pad202) ) ( 3 Net-(J2-Pad205) ) ( 4 Net-(U127-Pad2) ) ( 5 0VDCA ) ( 6 0VDCA ) ( 7 Net-(U127-Pad8) ) ( 8 Net-(J2-Pad204) ) ( 9 Net-(J2-Pad202) ) ( 10 +4VDC ) ) ) *

Step #4: Creation of a test bench. This is the point in a real simulation task where you would have to decide what it is you want from the simulation, and write a test bench file in Verilog to provide the appropriate inputs at the proper time to do the testing you have in mind. For the purpose of this example, though, we've simply provided a test-bench file, which looks like this:// Verilog module auto-generated for AGC module A1 by dumbVerilog.py module A1 ( rst, FS01_, F02A, F02B, FS02, FS02A ); input wire rst, FS01_; output wire F02A, F02B, FS02, FS02A; assign FS02A = rst ? 0 : ~(0|U126Pad7); assign FS02 = rst ? 0 : ~(0|U126Pad7|U127Pad8); assign U127Pad8 = rst ? 1 : ~(0|F02B|FS01_|U127Pad2); assign U126Pad7 = rst ? 1 : ~(0|U127Pad2|FS02); assign U127Pad2 = rst ? 0 : ~(0|U127Pad8|FS01_|F02A); assign F02A = rst ? 0 : ~(0|U126Pad7|U127Pad2); assign F02B = rst ? 0 : ~(0|U127Pad8|FS02); endmodule

// Test bench for testVerilog.v

`timescale 1us / 1ns

module testVerilog;

reg rst = 1;

initial begin

$dumpfile("testVerilog.vcd");

$dumpvars(0, testVerilog);

# 2 rst = 0;

# 500 $finish;

end

reg FS01_ = 0;

always #4.883 FS01_ = !FS01_;

wire F02A, F02B, FS02, FS02A;

A1 A1A (

rst, FS01_, F02A, F02B, FS02, FS02A

);

initial

$timeformat(-6, 0, " us", 10);

initial

$monitor("At time %t, rst=%d, FS01_=%d, F02B=%d, FS02=%d, FS02A=%d, FS02A=%d", $time, rst, FS01_, F02B, FS02, F02A, FS02A);

endmodule

Let's take a look at this file and see what it says. First,

the "timescale" directive explains how to understand the timings

(the things marked with "#") that appear within the test-bench

file. It says that the time scale will be 1 us, so that the

numbers for the "#" timings are in microseconds. VCD info: dumpfile testVerilog.vcd opened for output.Thus as promised, FS01/ toggles about very 5 microseconds, while FS02 toggles about every 10 microseconds.

At time 0 us, rst=1, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 2 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 5 us, rst=0, FS01_=1, F02B=1, FS02=0, FS02A=0, FS02A=0

At time 10 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

At time 15 us, rst=0, FS01_=1, F02B=0, FS02=1, FS02A=1, FS02A=1

At time 20 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 24 us, rst=0, FS01_=1, F02B=1, FS02=0, FS02A=0, FS02A=0

At time 29 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

At time 34 us, rst=0, FS01_=1, F02B=0, FS02=1, FS02A=1, FS02A=1

At time 39 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 44 us, rst=0, FS01_=1, F02B=1, FS02=0, FS02A=0, FS02A=0

At time 49 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

At time 54 us, rst=0, FS01_=1, F02B=0, FS02=1, FS02A=1, FS02A=1

At time 59 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 63 us, rst=0, FS01_=1, F02B=1, FS02=0, FS02A=0, FS02A=0

At time 68 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

At time 73 us, rst=0, FS01_=1, F02B=0, FS02=1, FS02A=1, FS02A=1

At time 78 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

At time 83 us, rst=0, FS01_=1, F02B=1, FS02=0, FS02A=0, FS02A=0

At time 88 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

At time 93 us, rst=0, FS01_=1, F02B=0, FS02=1, FS02A=1, FS02A=1

At time 98 us, rst=0, FS01_=0, F02B=0, FS02=0, FS02A=0, FS02A=0

...

At time 498 us, rst=0, FS01_=0, F02B=0, FS02=1, FS02A=0, FS02A=1

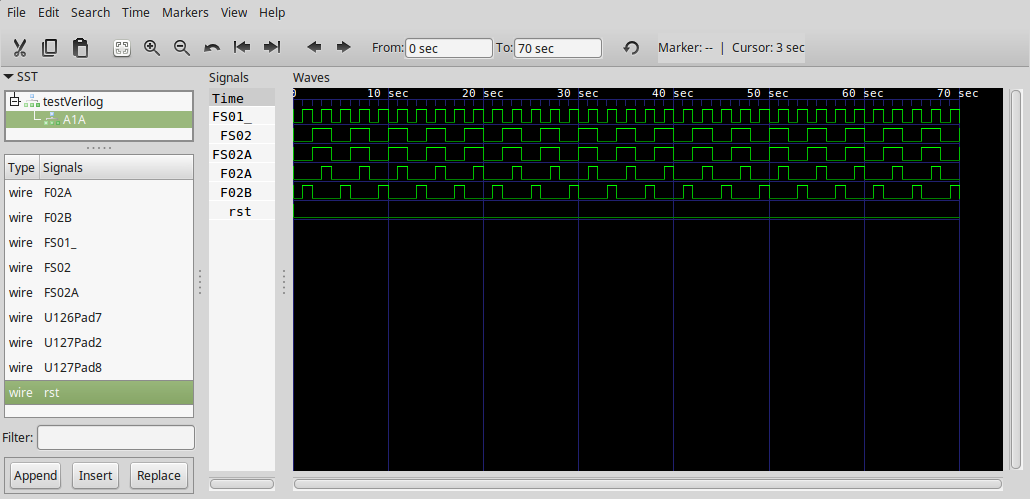

Step #7: Visualization. When the dump-file created by running the simulation, namely testVerilog.vcd, is pulled into the GTKWave visualization program, you see something like the following. The picture doesn't seem to require any explanation, though it's fun to compare it to the corresponding picture on p. 4-222A of document ND-1021042.

Aside: Simulation-result dumpfiles can be in a number of file-formats, with designations like VCD, LXT2, FST, and so on. You many notice that in the screenshot above, the simulation dumpfile is called "module.fst" rather than the "testVerilog.vcd" as the descriptive text above claims. A mixup on my part, I suppose! At any rate, the data depicted is what the text says it is!

For our discussion (and in our

repository for electrical schematics and Verilog descriptions of

them), we expect a certain directory hierarchy and

file-naming convention within that hierarchy. It looks like

this:

Top level directory of the repository/The items in green above are the ones that are either provided for you in our repository or are created more-or-less automatically for you by the process that will be described later on. The items in reddish-brown above may be partially created for you to give you a head start, but nevertheless require some active involvement on your part to get them just right, in those cases where you actually need the files. But in brief, the electrical design for any given part number of the AGC (such as 2003200 or 2003993) consists of a set of drawings of the individual circuit modules, plus the "backplane", i.e. the set of electrical interconnections between the modules. For AGC p/n 2003200, for example, those items are implemented by the Verilog files:

Scripts/

dumbVerilog.pySchematics/

dumbTestbench.py

roms/

Artemis072.v

Aurora12.v

...

Validation.v

Validation-hardware-simulation.v

DRAWING1/

DRAWING2/module.net

- ... schematics ...

module.init

tb.v

module.v

module_tb.v

module.vvp

... schematics ....

module.net

module.init

tb.v

module.v

module_tb.v

module.vvp

.

.

Makefile

2003200.v

tb-2003200.v

2003200.vvp

2003993.v

tb-2003993.v

2003993.vvp

.

.

.

Since this is something that has already been done for you, and

the repository has these files in it, there's not much you need to

know about it. So (lucky you!) I'm not actually going to

describe how to perform these steps.

However, here are some basic factoids that may or may not be of

interest:

The AGC's logic module circuits, modules A1-A24

mostly consist of so-called "combinational" logic, in which a

unique set of inputs determines a unique set of outputs at any

specific moment of time. However, some of the NOR gates,

such as those in the figure to the left (which is from the testVerilog example

given earlier), contain feedback in which the inputs to a NOR gate

may depend indirectly on its output. The net result is for

those portions of the circuit to have a kind of "memory", in which

the current output depends not just on the inputs at this precise

moment in time, but also on the inputs at earlier times as well.

The AGC's logic module circuits, modules A1-A24

mostly consist of so-called "combinational" logic, in which a

unique set of inputs determines a unique set of outputs at any

specific moment of time. However, some of the NOR gates,

such as those in the figure to the left (which is from the testVerilog example

given earlier), contain feedback in which the inputs to a NOR gate

may depend indirectly on its output. The net result is for

those portions of the circuit to have a kind of "memory", in which

the current output depends not just on the inputs at this precise

moment in time, but also on the inputs at earlier times as well.

When confronted with a situation like this, the Verilog simulator

software may not be able to initially figure out what the outputs

of the circuit are, because those depend on times before the

simulation started, about which the simulator software has no

information. In real life, such as in the real physical

AGC units, those circuits will settle very quickly into some

stable state. But in simulation that may not be the case,

and the circuit may oscillate endlessly. So we have to have

some way to initially get the system into some stable state in

which all of the feedback signals have some nice, consistent

values.

The way that is done is with module.init

files. Each schematic drawing needs to have one of

these. A module.init file can provide settings for any or

all of the NOR gates, driving their outputs to a desired state

when a signal ("rst") is initially applied to the circuit.

The way that is done is with module.init

files. Each schematic drawing needs to have one of

these. A module.init file can provide settings for any or

all of the NOR gates, driving their outputs to a desired state

when a signal ("rst") is initially applied to the circuit.

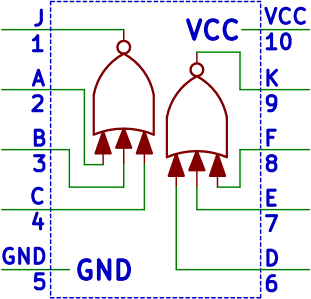

Before describing the format of the module.init files, though, we

need to agree on some basic facts about the NOR gates used in the

AGC circuits. The NOR gates are packaged into 10-pin

integrated circuits, each of which contains two independent NOR

gates, as in the figure to the right. One of the NOR-gates

outputs to the chip's pin 1 (called "J") on the schematics, while

the other NOR-gate outputs to pin 9 (or "K").

The other thing to notice is that, as in the figure to the left,

the dual NOR-gates are identified in the Verilog design by

reference designators like U1nn, U2nn, or U3nn,

where nn is a 2-digit number written on the NOR-gate's

schematic symbol. In the figure at left, for example, we

have both NOR gates from U127, both NOR gates from U128, both NOR

gates from U129, and one of the two NOR gates from U126. How

did I know that we had U127 rather than U227? Well, usually

U1nn is on the first sheet of the schematic and U2nn

is on the second sheet. However, to know for sure, you

really need to read the textual notes provided within the

schematic.

With those understandings in mind, here's a portion of a

module.init file for your consideration. (It does not

belong to the example figure above.)

# For module A2

U151 1 0 0.2

U152 0 0 0.2

U153 0 0 0.2

U155 1 0 0.2

U156 0 0 0.2

U157 1 0 0.2

U308 0 0

U309 0 0

U228 1 0

...

You can decorate the module.init file with comments (preceded by

"#") or blank lines, if it helps you document what's being

done. More importantly, the file can be edited in a

text-editor and consists of lines of the form

Unnn [ JVALUE [ KVALUE [ JDELAY [ KDELAY ]]]

by which I mean that the lines consist of the chip's reference

designator, follow by 0 to 4 numerical values. JVALUE and

KVALUE are simply the values of the NOR gates' outputs at

reset, and always have the settings 0 or 1. 0 is the

default, meaning that the output of the NOR is LOW.

How does one determine what values JVALUE and KVALUE

should be given? What you are looking for, minimally, is

that all of the outputs from the NOR gates should be consistent

with their inputs. You know that that's possible, since the

original AGCs didn't simply oscillate out of control, But

how?

One way is to use a handy script we've provided,

Scripts/dumbInitialization.py, which I describe in more detail in

the Appendix.

This was the method used to create the module.init files presently

in the repository. But if the initializations created this

way don't satisfy you, you can edit them according to your own

liking, because they're just text files. It is certainly a

drawback of dumbInitialization.py that the initializations aren't

necessarily "natural", since the only guarantee is that they are

mutually consistent rather than to have any other properties you

might like. For example, module A1 is basically just a

33-bit counter, and that counter is initialized to some "random"

value by dumInitialization.py, whereas you might like it

to be initialized to 0. I fear that's just a consequence of

how the flip-flops were implemented in the AGC, as there's nothing

(as far as I know) that guarantees how they're initialized.

And sadly, I have nothing other than that smug platitude to offer

you about creating your own custom initializations.

What are JDELAY and KDELAY? Well, they have

to do with a completely different topic. The Verilog

description of the design allows you to assign any gate delay you

like to any of the NOR gates. Mostly it isn't critical, and

the default we use is a delay of 0. But in some cases it is

critical that it be non-zero, or even that it is confined within a

narrow range of acceptable values. The units of time are

defined by the "timescale" operative that appears near the top of

many of the Verilog files. Usually this is 100 ns per

simulator timer tick. Therefore, for example, a JDELAY

or KDELAY of 0.1 would be 10 ns.

A "test bench" is a Verilog file that lets you define how to

stimulate the inputs of the Verilog file(s) for an individual AGC

module or combination of AGC modules, and therefore to produce

outputs that you can either view immediately or log for later

analysis/viewing. When you compile the Verilog file for the

test bench along with the Verilog file(s) it is the test bench

for, you get a file that can be used to simulate the design

without further ado.

Unfortunately, I cannot tell you much about how to write Verilog

test-bench files, since it's going to depend so much on the

particular AGC p/n or AGC module or PCB you're trying to test, and

what you're trying to test within it. You'll simply have to

research these topics for yourself.

I will tell you that the software repository does have template

testbench files (produced by the script dumbTestbench.py as

described in the preceding section) that you can use as starting

points, or else completely-working testbench files in a few cases,

wherever it makes sense in the present state of development to do

so:

Alas! there's one point in the simulation where we depart

somewhat from absolute verisimilitude with respect to the original

AGC circuitry, and that's in the simulation of the AGC's erasable

memory (the "RAM") and fixed memory (the "ROM"). Because the AGC's

memory was made from Permalloy-wire cores, surrounded by lots of

analog circuitry to drive them and to sense their states, it

becomes a bit tricky to simulate their behavior in essentially

digital simulation tools like Icarus Verilog.

What's done in the simulation instead is to continue to use the

digital signals that the AGC feeds into the analog circuitry

driving the cores or extracts from the analog circuitry sensing

the cores, but to replace the cores themselves and their

surrounding analog circuitry with a

fully digital model whose schematics and associated Verilog can

be found in the github repository. Specifically, the

fixed memory ends up being modeled

after a Microchip SST39VF200A flash-memory chip (Verilog

module ROM.v), not that the choice of this specific part has too

much significance, as long as it has sufficient capacity. As

far as the contents of the memory are concerned, it can be

any of the AGC programs available to us in the Virtual AGC

project: Artemis 072, Aurora 12, Colossus 237, etc.

It's only necessary to make sure that the particular Verilog file

implementing the desired AGC program is present in the

Schematics/roms/ folder at compile time, and is named

"rom.v". For convenience, each

of the available AGC programs has been converted into the form

needed for the Verilog to use them, and can be selected at

the time the Verilog is compiled (see the next section).

It is worth noting, though, that the simulation of the

electronics runs very slowly relative to real time, and

that there isn't presently any way to model an interactive DSKY in

the simulation, so the choice of which AGC programs to use is

really limited greatly by which of them are easy to use,

pragmatically speaking. The AGC program called

"Validation-hardware-simulation" is one such program: it has been

modified to operate without DSKY input, and only require about 40

seconds to run in real life. In the simulation, it requires

much, much more time.

But if you're running Windows or just want to know how to do the

steps yourself, that doesn't really help you too much.

(Unless somebody wants to fix up a Windows version of the Makefile

for me? It shouldn't be too hard, but I don't want to mess with

Windows myself, so it's left as an exercise for the reader.)

For you folks, here's how the compilation step works.

There are really two cases of interest. First, you might

want to simulate a single AGC module, to exercise its functions

and perhaps to debug it. For concreteness, let's imagine

that this module has drawing number 2005123A, and hence its files

reside in the directory Schematics/2005123A. There will be

two relevant files in that directory: module.v, which is the

Verilog of the module itself, automatically translated from the

CAD files for drawing 2005123A, and module_tb.v, the Verilog file

of the "test bench" of the module. As explained earlier,

there will be either an automatically-generated version of the

test bench or else a manually tweaked version of the test bench

file already in place. But it's up to you to insure that the

test bench does what you want. The compilation is simple:

cd Schematics/2005123A

iverilog -o module.vvp module_tb.v module.v

which produces an object file, Schematics/2005123A/module.vvp.

The second case is simulation of a complete AGC unit. Let's

suppose that this is the AGC with p/n 2003200. AGC p/n is

essentially a collection of various AGC modules, plugged into a

"backplane". Module A1 is drawing 2005259A, module A2 is

drawing 2005260A, etc., up through module A24, drawing

2005273A. As above, there is a testbench file, 2003200.v,

which represents the backplane, along with any stimulation you

need to apply to the backplane symbols, and any probing you need

to do on those signals. So here is what the Verilog

compilation looks like:

cd Schematics

iverilog -o 2003200.vvp 2003200.v 2005259A/module.v 2005260A/module.v ... 2005273A/module.v

This produces an object file, Schematics/2003200.vvp.

cd Schematics/2005123Awhile to simulate AGC p/n 2003200 we'd do this:

vvp module.vvp

cd SchematicsDepending on your intentions — i.e., how the testbench is written — the simulation may or may not be a hands-off operation. Typically, though, it would result either in messages printed out to the terminal or creation of a log file for later viewing and analysis, or both.

vvp 2003200.vvp -lxt2

Assuming that your simulation produces a log file for later

viewing or analysis, there are several choices.

For example, as mentioned in the preceding section, a VCD log

file is ASCII, and therefore very suited for some kind of

post-processing with scripts written in AWK or Python or some

other language.

Often, though, it's nicer to just view some set of signals of

interest as if using an oscilloscope or logic analyzer. A

program like GTKWave is great for this, in that it can view either

VCD or LXT2 files, and you can select the specific signals you

want to view, and the ordering of those signals. For the

examples we've been using, you'd do one of the following and then

just monkey around in GTKWave's GUI:

cd Schematics/2005123A

gtkwave module.vcd

or

cd Schematics

gtkwave 2003200.lxt2

cd Schematicsor perhaps

make

cd SchematicsIf you're a bit less lucky, you'd probably have to run our netlist-to-Verilog translation script manually. This is the Python 3 script Scripts/dumbVerilog.py, and taking into account our directory and file-naming conventions, you'd do this:

make clean all

cd Schematics/DRAWING_NUMBERThe only things that really need to be filled in here are the AGC MODULE number (A1, A2, ..., A24) and the default gate DELAY. The unit in which DELAY is expressed ultimately depend upon the time-scale that will eventually be set in the test bench. Now, the basic AGC clock speed is 1.024 MHz, but the simulation cycle time must then be 2.048 MHz, since that's the rate at which the clock toggles. For this reason, all test bench Verilog automatically produced (see the next section) uses a basic time-scale of 100 ns. The nominal gate delay of AGC NOR gates was 20 ns., so that means a reasonable DELAY might be 0.2, and therefore that's what we typically use.

../../Scripts/dumbVerilog.py MODULE module.net ../..Scripts/pins.txt DELAY module.init >module.v

A consistent set of flip-flop initializations can conveniently be

generated using the Python 3 script

Scripts/dumbInitialization.py. If you are running Linux then

the simplest thing to do (for, say, AGC model 2003200) is just

cd Schematics

make clean all

make 2003200.init

make clean all

Of course, if you don't have Linux then this doesn't help you too

much, so let's consider how to go about generating the flip-flop

initialization files (DRAWING/module.init) as a manual

operation rather than using the handy-dandy Makefile. The

basic syntax is simply

dumbInitialization.py <INPUT.v

However, this simple statement hides some inconvenient

complexity. Using dumbInitialization.py to create an

initialization file requires having the Verilog for the circuit at

hand, whereas generating the Verilog for the circuit requires

having the initialization file at hand! Fortunately, this

circle is not as vicious as it appears, since all you really have

to do is this:

That's why in the Makefile example we started with, there are two

"make clean all" steps.

There are two basic scenarios for which you'd want to generate

initialization files, I think: You might want an

initialization file for an AGC module considered as a stand-alone

unit. Or, you might want an initialization file for the

complete set of AGC modules of a given AGC part number. The

latter has an advantage over the former, in that the

initialization is internally consistent throughout the entire

AGC. Besides, an initialization file of the full-AGC type

works perfectly well for an individual module, but not

vice-versa. So let's assume you really want initialization

files for the AGC as a whole.

The first step, of course, is to take all of the Verilog files

for the individual AGC modules, and concatenate them to form one

large file. For AGC model 2003200, for example, those files

are 2005259A/module.v, 2005260A/module.v, ...,

2005273A/module.v. (The drawing numbers for the AGC modules,

which is essentially what these are, are listed both on the Electro-Mechanical page of

the website, and in Schematics/Makefile.) You can combine

these files, for example, using a text-editor program. The

second step is to actually run dumbInitialization.py:

Scripts/dumbInitialization.py < BigCombinedVerilogFile.vThe result is the creation of files files A1.init, A2.init, ..., A24.init. These need to be copied into the appropriate drawing directories and be renamed to module.init. For example, A1.init might become 2005259A/module.init.

Scripts/dumbTestbench < BigCombinedVerilogFile.v > Testbench.vSuch a testbench probably still needs considerable tweaking, but it's a good place to start.